Longest Lasting House Siding A Comprehensive Guide

Longest lasting house siding is a crucial consideration for homeowners, balancing aesthetics, budget, and long-term value. Choosing the right siding material significantly impacts your home’s curb appeal, energy efficiency, and overall lifespan. This guide delves into the intricacies of various siding options, helping you make an informed decision that protects your investment for decades to come. We’ll explore material durability, installation techniques, maintenance requirements, environmental factors, and the crucial cost-benefit analysis to ensure you choose the best siding for your specific needs and climate.

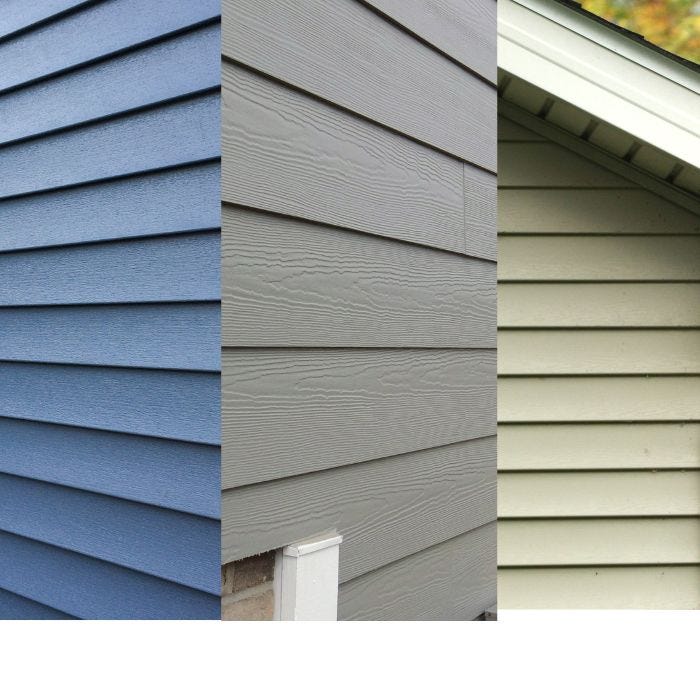

From the initial selection process to the long-term maintenance, understanding the nuances of each siding material—wood, vinyl, fiber cement, metal, and brick—is paramount. This guide will equip you with the knowledge to compare lifespans, costs, and maintenance needs, ultimately empowering you to choose the siding that best fits your home and lifestyle.

Material Durability: Longest Lasting House Siding

Choosing the right siding for your home is a significant investment, impacting both its aesthetic appeal and longevity. Understanding the durability of different siding materials is crucial for making an informed decision. This section will compare the lifespan, cost, and maintenance requirements of various siding options, helping you determine the best fit for your needs and climate.

Siding Material Comparison

The lifespan of siding significantly varies depending on the material used and the environmental conditions. The following table provides a general overview. Keep in mind that these are estimates, and actual lifespan can be affected by factors like installation quality and regular maintenance.

| Material | Lifespan (years) | Cost (relative) | Maintenance Requirements |

|---|---|---|---|

| Wood | 15-50+ | Medium to High | High; regular painting, staining, and potential repairs |

| Vinyl | 20-40 | Low to Medium | Low; occasional cleaning |

| Fiber Cement | 30-50+ | Medium to High | Medium; occasional cleaning and repainting may be needed |

| Metal | 30-50+ | Medium to High | Low to Medium; occasional cleaning and potential spot repairs |

| Brick | 50+ | High | Low; minimal maintenance required |

Factors Influencing Siding Longevity

Several factors contribute to the longevity of different siding materials. Understanding these factors will allow for a more accurate assessment of lifespan expectations in specific climates.

UV Resistance: Prolonged exposure to ultraviolet (UV) radiation from sunlight can degrade siding materials. Vinyl siding is particularly susceptible to UV damage, leading to fading and cracking. Wood siding requires regular painting or staining to protect it from UV rays. Fiber cement and metal siding generally offer better UV resistance.

Moisture Resistance: Moisture can cause significant damage to siding, leading to rot, mold, and mildew. Wood siding is highly susceptible to moisture damage unless properly treated and maintained. Vinyl siding is generally resistant to moisture, but prolonged exposure to standing water can cause issues. Fiber cement siding is more moisture-resistant than wood but can still be affected by prolonged exposure. Metal siding is highly resistant to moisture damage.

Impact Resistance: The ability of siding to withstand impacts from hail, debris, or accidental damage varies significantly. Wood siding is relatively susceptible to dents and damage. Vinyl siding can crack or dent under impact. Fiber cement siding offers good impact resistance. Metal siding provides excellent impact resistance.

Visual Representation of Siding Degradation

Imagine a visual representation showing five different siding materials (wood, vinyl, fiber cement, metal, and brick) over a 50-year period.

Year 0: All siding materials appear new and in pristine condition. Colors are vibrant, and surfaces are smooth.

Year 10: Wood siding shows minor signs of weathering, with some fading and discoloration. Vinyl siding may have minor discoloration. Fiber cement, metal, and brick show minimal to no visible degradation.

Year 20: Wood siding shows more significant fading, potential cracking, and possible signs of rot in areas exposed to moisture. Vinyl siding shows more noticeable fading and may have some minor cracking. Fiber cement and metal show minimal wear. Brick remains largely unchanged.

Year 30: Wood siding may require repainting or significant repairs. Vinyl siding shows increased fading and cracking. Fiber cement siding may show minor surface imperfections. Metal siding might have some minor surface corrosion or discoloration. Brick shows minimal wear.

Year 50: Wood siding is likely in need of significant repair or replacement. Vinyl siding is showing considerable degradation, with extensive fading and cracking. Fiber cement siding shows some signs of wear, but remains largely intact. Metal siding may have some corrosion but is generally still functional. Brick remains largely unchanged, showcasing its remarkable longevity.

Installation Techniques and Quality

Source: octanecdn.com

Proper installation is paramount to achieving the maximum lifespan of any house siding, regardless of its inherent material durability. Even the longest-lasting siding will fail prematurely if not installed correctly. Careful attention to detail during installation significantly impacts the longevity and performance of your home’s exterior.

The quality of installation directly affects the siding’s resistance to water damage, wind uplift, and general wear and tear. Neglecting proper installation techniques can lead to costly repairs, reduced energy efficiency, and an unsightly appearance. Understanding and implementing best practices is crucial for a successful and long-lasting siding project.

Common Installation Mistakes and Their Consequences

Improper installation can significantly shorten the lifespan of even the most durable siding. Common mistakes include inadequate flashing around windows and doors, leading to water intrusion; incorrect spacing of fasteners, resulting in buckling or warping; and failure to properly seal joints, allowing moisture penetration. These issues can lead to rot, mold growth, and premature siding failure, necessitating expensive repairs or even complete siding replacement. For example, improperly installed vinyl siding can buckle in hot weather due to inadequate expansion space, while improperly flashed fiber cement siding can suffer from water damage and rot within a few years.

Preparing the Underlying Structure for Long-Lasting Siding

Before installing any siding, preparing the underlying structure is crucial for long-term performance. This involves ensuring the sheathing is sound, level, and properly fastened. Damaged or deteriorated sheathing must be replaced. Furthermore, proper flashing is essential to divert water away from vulnerable areas like windows, doors, and corners. Using high-quality flashing materials and installing them correctly prevents water penetration and protects the underlying structure. For example, a continuous layer of flashing should be installed behind all siding courses at window and door openings. This prevents water from seeping behind the siding and damaging the wall assembly.

Step-by-Step Installation of Fiber Cement Siding

Fiber cement siding offers excellent durability and longevity. This guide Artikels the installation process, emphasizing crucial details for long-term performance.

- Preparation: Ensure the underlying sheathing is sound, level, and properly fastened. Repair or replace any damaged areas. Install building paper or a suitable weather barrier.

- Flashing: Install flashing around windows, doors, and other penetrations. Use continuous flashing behind all siding courses at these locations, extending it several inches beyond the siding. Properly seal all joints with a high-quality sealant.

- Starter Strip: Install a starter strip along the bottom of the wall to provide a level base for the first row of siding.

- Siding Installation: Begin installing the siding panels from the bottom, working upwards. Ensure proper overlapping and alignment of panels. Use corrosion-resistant nails or screws, spaced according to manufacturer’s specifications. Avoid overdriving fasteners.

- Caulking and Sealing: Seal all joints and gaps between siding panels and around windows and doors using a high-quality, paintable exterior-grade caulk. This prevents water intrusion and ensures a weathertight seal.

- Finishing: Install J-channels, corner trim, and other accessories as needed. Ensure all joints and seams are properly sealed.

Properly installed fiber cement siding, with meticulous attention to flashing and sealing, can last for 50 years or more.

Maintenance and Repair

Source: alumtech.ca

Proper maintenance is crucial for extending the lifespan of your house siding, regardless of the material. Regular cleaning, inspection, and timely repairs can prevent minor issues from escalating into costly replacements. This section details a maintenance schedule and common repair procedures for various siding types.

Regular Maintenance Schedules

A proactive maintenance approach significantly impacts siding longevity. Different siding materials require slightly different care, but a consistent schedule incorporating cleaning and inspection is universally beneficial.

- Vinyl Siding: Requires annual cleaning with a mild detergent solution and a soft-bristled brush. Inspect for cracks, loose panels, or damage from impact. Power washing should be done cautiously, avoiding high pressure that could damage the siding.

- Wood Siding: Needs more frequent attention, ideally semi-annual cleaning and inspection. Wood is susceptible to rot, insect infestation, and moisture damage. Regular staining or painting is necessary to protect it from the elements. Inspect for signs of decay, loose nails, or insect activity.

- Fiber Cement Siding: Relatively low-maintenance, requiring annual cleaning with a mild detergent and brush. Inspect for cracks, chips, or loose panels. Fiber cement is durable but can be susceptible to damage from impact.

- Metal Siding: Generally the most low-maintenance option. Annual cleaning with soap and water is sufficient. Inspect for dents, scratches, or rust. Metal siding is resistant to many forms of damage, but impact can still cause issues.

Common Siding Problems and Repair Methods

Understanding common siding problems and their solutions is essential for effective maintenance.

- Cracks: Cracks in vinyl or fiber cement siding can often be repaired with caulk designed for the specific material. Larger cracks in wood siding may require replacement of the damaged section. For metal siding, small dents might be repairable with a hammer and dolly, while larger dents may necessitate panel replacement.

- Fading: Fading is common in wood and vinyl siding due to prolonged sun exposure. Repainting or restaining wood siding restores its color and protects it from further damage. Vinyl siding fading is more difficult to address, often requiring replacement of severely faded panels.

- Water Damage: Water damage manifests as rot in wood siding, swelling in vinyl siding, or rust in metal siding. Addressing water damage requires identifying and fixing the source of the leak, followed by repairing or replacing the affected siding sections. Prompt action is critical to prevent further damage.

Annual Siding Inspection Checklist, Longest lasting house siding

A thorough annual inspection helps identify potential problems before they become major issues.

- Check for cracks, chips, or holes in the siding. Note the location and severity of any damage.

- Inspect for loose or damaged caulking around windows and doors. Reapply caulk as needed to prevent water infiltration.

- Examine the siding for signs of water damage, such as discoloration, swelling, or rot. Address any water damage promptly to prevent further deterioration.

- Look for signs of insect infestation, such as holes or insect droppings. Consult a pest control professional if necessary.

- Assess the overall condition of the paint or stain on wood siding. Repaint or restain as needed to protect the wood.

- Check for loose or damaged flashing around chimneys, vents, and other roof penetrations. Flashing is crucial for preventing water damage.

- Inspect the foundation for cracks or settling that could put stress on the siding. Address any foundation issues with a qualified professional.

Environmental Factors and Location

Source: optimole.com

Choosing the right siding for your home involves understanding how environmental factors and your geographic location significantly impact its longevity. Different materials react differently to extreme weather conditions, and a siding that performs exceptionally well in one climate might fail prematurely in another. This section will explore these crucial considerations.

Environmental factors play a dominant role in determining the lifespan of your house siding. Exposure to harsh elements accelerates degradation, leading to premature wear and tear. Understanding these factors is key to making an informed decision about the most suitable siding material for your specific location.

Extreme Temperatures and Their Effects on Siding Materials

Extreme temperatures, both high and low, can cause significant damage to siding. High temperatures can cause expansion and contraction in some materials, leading to cracking and warping. Conversely, extremely low temperatures can embrittle certain materials, making them more susceptible to cracking and damage from impact. For instance, vinyl siding can become brittle in very cold climates, while wood siding might expand and contract significantly, leading to gaps and potential water damage. Metal sidings, such as aluminum or steel, generally handle temperature fluctuations better but can be susceptible to expansion and contraction, particularly over long periods.

Humidity and Moisture’s Impact on Siding Durability

High humidity levels contribute to the growth of mold, mildew, and fungi on many siding materials, especially wood and fiber cement. Moisture can penetrate siding, leading to rot, warping, and structural damage. Coastal areas, known for their high humidity, require siding materials with excellent moisture resistance. Materials like vinyl and certain engineered wood sidings offer better protection against moisture penetration compared to untreated wood. Proper installation techniques, such as ensuring adequate ventilation and using appropriate flashing, are also crucial in minimizing moisture damage regardless of the siding material chosen.

Wind and Sunlight Exposure

Strong winds can damage siding through direct impact, especially loose or improperly installed materials. Wind-driven rain can further exacerbate the problem by forcing water behind the siding. Prolonged exposure to sunlight, particularly ultraviolet (UV) radiation, can cause fading, discoloration, and degradation of many siding materials, especially those made from organic materials like wood. Darker colored sidings tend to absorb more heat and are therefore more susceptible to UV damage. Some manufacturers offer siding materials with UV-resistant coatings to mitigate these effects.

Geographical Location and Siding Selection

Geographical location significantly influences siding selection. Coastal areas, with their high humidity, salt spray, and strong winds, require materials resistant to corrosion and moisture damage. Vinyl, fiber cement, and certain types of metal siding are good choices for coastal regions. Mountainous regions, often characterized by heavy snowfall and extreme temperature fluctuations, necessitate siding with excellent durability and resistance to impact. Materials such as engineered wood or certain types of metal siding can withstand these harsh conditions. Areas prone to wildfires necessitate fire-resistant materials, such as certain types of metal or fiber cement siding.

Climate Change and Future Siding Durability

Climate change is expected to intensify extreme weather events, including more frequent and intense heatwaves, storms, and periods of heavy rainfall. This will put increased stress on all types of siding materials. For example, more frequent and intense storms could lead to increased damage from wind and rain. Rising temperatures could exacerbate the effects of heat on certain materials, leading to faster degradation. Therefore, choosing siding materials with enhanced durability and resistance to extreme weather conditions is becoming increasingly important to ensure long-term performance and minimize future maintenance and repair costs. This might involve selecting materials with higher UV resistance, improved water resistance, or greater impact strength. For example, the increased frequency of hurricanes in some regions necessitates the selection of siding materials that can withstand high winds and potential water damage.

Cost-Benefit Analysis

Source: smartextpros.com

Choosing the right siding involves careful consideration of both upfront costs and long-term expenses. Understanding the cost-benefit relationship between different materials is crucial for making a financially sound decision that aligns with your budget and long-term goals. This analysis will help you compare various long-lasting siding options, considering their initial investment, ongoing maintenance, and overall lifespan.

A comprehensive cost-benefit analysis goes beyond simply comparing initial prices. It requires a long-term perspective, factoring in the anticipated lifespan of the siding, the frequency and cost of necessary repairs and maintenance, and even potential resale value increases associated with higher-quality materials. This approach ensures you make an informed decision that optimizes both your immediate and future financial well-being.

Comparison of Siding Costs Over 50 Years

The following table provides a comparative analysis of the initial and long-term costs associated with several durable siding materials. Note that these figures are estimates and can vary based on factors such as material quality, labor costs in your region, and the size of your house. Always obtain multiple quotes from reputable contractors before making a decision.

| Material | Initial Cost (Estimate) | Annual Maintenance Cost (Estimate) | Total Cost over 50 Years (Estimate) |

|---|---|---|---|

| Fiber Cement | $15,000 – $25,000 | $100 – $300 | $20,000 – $45,000 |

| Vinyl | $8,000 – $15,000 | $50 – $150 | $12,500 – $27,500 |

| Engineered Wood | $12,000 – $20,000 | $150 – $400 | $19,500 – $40,000 |

| Brick | $25,000 – $40,000 | $50 – $100 | $27,500 – $50,000 |

Return on Investment (ROI) Calculation

Calculating the ROI for different siding options helps quantify the financial return over the material’s lifespan. A higher ROI indicates a more cost-effective choice in the long run. The following formula can be used to estimate ROI:

ROI = [(Total Value After – Total Cost) / Total Cost] x 100%

For example, let’s consider fiber cement siding with an initial cost of $20,000 and a total cost over 50 years of $40,000. Assuming the increased resale value of the home due to the upgraded siding is $15,000, the calculation would be:

ROI = [($20,000 + $15,000 – $40,000) / $40,000] x 100% = -12.5%

In this example, the ROI is negative, indicating that the increased resale value did not fully offset the total cost. However, this is just an example; different scenarios with higher resale values or lower maintenance costs can result in positive ROI. Always factor in your specific circumstances when calculating ROI.

Factors Beyond Cost

While cost is a significant factor, several other considerations influence the optimal siding choice. These non-monetary aspects can significantly impact your satisfaction and the overall value of your home.

Aesthetic appeal is a crucial consideration. The siding’s color, texture, and style should complement your home’s architecture and your personal preferences. Energy efficiency is another important factor; some siding materials offer better insulation than others, leading to potential energy savings over time. For instance, fiber cement siding often provides superior insulation compared to vinyl. Furthermore, durability, ease of maintenance, and resistance to environmental factors (like moisture and pests) all contribute to the long-term value and appeal of your siding.

Concluding Remarks

Selecting the longest lasting house siding involves careful consideration of numerous factors, extending beyond initial cost to encompass long-term maintenance, environmental impact, and aesthetic preferences. By understanding the strengths and weaknesses of different materials, and by implementing proper installation and maintenance practices, you can significantly extend the lifespan of your home’s exterior and protect your investment. This guide provides a framework for making an informed decision, leading to a beautiful and durable home exterior for years to come. Remember to always consult with professionals for specific guidance tailored to your home and location.

Questions and Answers

Can I mix and match different siding materials on my house?

While possible, mixing siding materials requires careful planning and execution to ensure seamless transitions and prevent future issues. Consult a professional for advice on compatibility and proper installation techniques.

How often should I inspect my siding for damage?

Annual inspections are recommended, especially after severe weather events. Look for cracks, discoloration, loose or damaged sections, and signs of water damage.

What’s the best way to clean different types of siding?

Cleaning methods vary depending on the material. Gentle washing with soap and water is generally suitable for most, but avoid harsh chemicals. Always check the manufacturer’s recommendations.

Does homeowner’s insurance cover siding damage?

Coverage depends on your policy and the cause of the damage. Wind, hail, and fire damage are often covered, while general wear and tear usually isn’t. Review your policy details.

How does climate change affect siding longevity?

Increased frequency and intensity of extreme weather events (e.g., hurricanes, wildfires) can significantly shorten siding lifespan. Choosing materials with high resistance to these factors is crucial.