Best Siding for Manufactured Homes

Best siding for manufactured homes is a crucial decision impacting both aesthetics and longevity. Choosing the right material requires careful consideration of several factors, from climate and budget to maintenance and style. This guide explores the various siding options available, helping you make an informed choice that enhances your home’s curb appeal and protects your investment for years to come. We’ll delve into the pros and cons of popular materials like vinyl, aluminum, fiber cement, and wood, offering practical advice on installation, maintenance, and design considerations specific to manufactured homes.

Understanding the unique challenges and opportunities presented by manufactured home construction is key to selecting the ideal siding. We’ll cover everything from dealing with potential moisture issues to maximizing energy efficiency, all while keeping your budget and personal style in mind. Whether you’re aiming for a modern, rustic, or traditional look, we’ll show you how to achieve the perfect balance of functionality and beauty.

Types of Siding Suitable for Manufactured Homes

Choosing the right siding for your manufactured home is a crucial decision impacting its aesthetics, durability, and overall value. The ideal siding will offer a balance of protection from the elements, low maintenance, and visual appeal, all within a budget that suits your needs. Several materials are commonly used, each with its own set of advantages and disadvantages. Understanding these differences will help you make an informed choice.

Siding Material Comparison

The following table compares common siding materials used on manufactured homes, considering factors like durability, maintenance requirements, and cost. Remember that prices can vary significantly based on location, quality, and installation.

| Material | Pros | Cons | Typical Cost (per sq ft) |

|---|---|---|---|

| Vinyl | Low maintenance, affordable, variety of colors and styles, relatively easy installation. | Can fade or crack in extreme temperatures, susceptible to damage from impact, may not be as durable as other options. | $1-$4 |

| Aluminum | Durable, resistant to fire, insects, and rot, low maintenance, relatively long lifespan. | Can dent easily, susceptible to scratches, may not offer the same aesthetic appeal as other materials, can be noisy in rain or hail. | $2-$6 |

| Fiber Cement | Extremely durable, fire-resistant, resists insects and rot, low maintenance, can mimic the look of wood. | More expensive than vinyl or aluminum, heavier and more difficult to install, requires professional installation for optimal results. | $4-$8 |

| Wood | Aesthetically pleasing, natural look and feel, can be customized with paint or stain. | High maintenance, susceptible to rot, insects, and fire, requires regular painting or staining, more expensive than other options. | $6-$12+ |

Lifespan and Warranty Considerations

The lifespan of siding varies considerably depending on the material, quality of installation, and environmental conditions. Warranties offered by manufacturers also differ. Vinyl siding typically comes with a 20-30 year warranty, while aluminum siding may offer a similar or slightly longer warranty. Fiber cement siding often carries a 50-year warranty, reflecting its superior durability. Wood siding warranties are less standardized and depend heavily on the type of wood and the protective treatments applied. It’s crucial to carefully review the warranty details before making a purchase. For example, a 50-year warranty might only cover material defects and not damage caused by improper installation or extreme weather events.

Factors Influencing Siding Choice for Manufactured Homes: Best Siding For Manufactured Home

Source: com.au

Choosing the right siding for your manufactured home is a crucial decision impacting its longevity, aesthetics, and overall value. Several factors must be carefully considered to ensure a successful and cost-effective outcome. This section will explore the key elements influencing siding material selection.

Climate Considerations

Climate significantly impacts siding performance. Extreme temperatures, high humidity, and heavy snowfall necessitate choosing durable and weather-resistant materials. In regions with scorching summers, materials with high heat reflectivity, such as certain types of vinyl or aluminum siding, can help keep the home cooler and reduce energy costs. Conversely, in areas with harsh winters, siding that can withstand freezing temperatures, ice, and heavy snow loads, like fiber cement or engineered wood, are preferable. Coastal areas prone to high winds and salt spray require siding with excellent resistance to corrosion and damage from moisture. For example, a home in Florida might benefit from impact-resistant vinyl siding to withstand hurricanes, while a home in Minnesota would be better suited to durable, insulated vinyl or fiber cement siding to withstand harsh winters.

Architectural Style and Design

The architectural style of your manufactured home plays a vital role in determining suitable siding. A modern, minimalist design might look best with sleek, smooth siding like aluminum or fiber cement panels. Conversely, a more traditional or craftsman-style home might be enhanced by the texture and warmth of wood siding (properly treated for durability) or vinyl siding designed to mimic wood grain. The siding color and texture should complement the home’s overall design and enhance its curb appeal. For instance, a ranch-style home might look best with horizontal siding, while a Victorian-style home might benefit from vertical or more ornate siding patterns.

Budget and Cost-Effectiveness

Siding costs vary significantly depending on the material chosen, installation complexity, and regional pricing. Vinyl siding is generally the most affordable option, offering a good balance of cost and durability. Fiber cement siding provides superior durability and fire resistance but comes at a higher price point. Wood siding, while aesthetically pleasing, requires regular maintenance and can be expensive, especially for higher-quality, long-lasting woods. When budgeting, consider not only the initial cost of the siding but also the long-term maintenance and replacement costs. For example, a homeowner with a limited budget might opt for vinyl siding, while one prioritizing longevity and minimal maintenance might choose fiber cement.

Local Building Codes and Regulations

Compliance with local building codes and regulations is paramount when selecting siding. These codes often specify requirements for fire resistance, wind resistance, and energy efficiency. Before making a final decision, consult with your local building department to ensure your chosen siding material meets all applicable codes and obtain necessary permits. Ignoring these regulations can lead to delays, fines, and potential safety hazards. For example, certain areas might mandate fire-resistant siding in high-risk zones or require specific insulation levels within the siding system.

Installation and Maintenance of Siding on Manufactured Homes

Source: ctfassets.net

Proper installation and regular maintenance are crucial for extending the lifespan and preserving the aesthetic appeal of your manufactured home’s siding. Different siding materials require specific installation techniques and maintenance routines. Understanding these nuances will ensure your home remains protected and beautiful for years to come.

Vinyl Siding Installation

Vinyl siding is a popular choice for manufactured homes due to its affordability and low maintenance. The installation process, while generally straightforward, requires careful attention to detail to ensure a long-lasting, watertight seal. Improper installation can lead to issues like warping, cracking, and water damage.

- Preparation: Begin by thoroughly cleaning the existing exterior walls, ensuring they are free from debris and loose paint. Any necessary repairs to the underlying sheathing should be completed before siding installation commences.

- Starter Strip Installation: Install a starter strip along the bottom edge of the wall, providing a level and consistent base for the first row of siding panels.

- Siding Panel Installation: Install the vinyl siding panels, overlapping each panel slightly and ensuring proper alignment with the starter strip and adjacent panels. Use appropriate fasteners, typically nails or screws, spaced according to manufacturer’s recommendations. Over-fastening can cause warping.

- J-Channel and Corner Trim: Install J-channel along the edges of the walls and around corners to provide a neat finish and protect the edges of the siding panels.

- Finishing Trim: Install finishing trim pieces, such as window and door casings, to complete the installation. These pieces should be carefully aligned and secured to ensure a professional look.

- Caulking: Apply high-quality caulk to seal any gaps or seams between siding panels and trim pieces, preventing water intrusion.

Maintenance of Different Siding Types

Regular maintenance is essential to keep your siding looking its best and to prevent costly repairs down the road. The frequency and specific tasks will vary depending on the siding material.

Vinyl Siding: Vinyl siding is relatively low-maintenance. Regular cleaning with a garden hose and a soft brush will remove dirt and debris. For stubborn stains, a mild detergent solution can be used. Avoid abrasive cleaners or harsh chemicals, which can damage the vinyl. Inspect the siding regularly for any signs of damage, such as cracks or holes, and repair them promptly.

Aluminum Siding: Aluminum siding is also durable and requires minimal maintenance. Regular cleaning with soap and water is sufficient. Inspect for any signs of rust or corrosion and address them immediately. Aluminum siding can be repainted to refresh its appearance.

Fiber Cement Siding: Fiber cement siding is a durable and fire-resistant option. Regular cleaning with a soft brush and water is usually enough. However, it’s important to inspect for cracks and damage, as fiber cement is more susceptible to water damage than vinyl or aluminum. Repair or replace damaged sections promptly.

Troubleshooting Common Siding Problems

Addressing siding problems promptly can prevent minor issues from escalating into major, costly repairs.

Cracks: Cracks in siding can be caused by impact, settling, or expansion and contraction due to temperature changes. Small cracks can often be repaired with caulk or patching compounds. Larger cracks may require replacing the damaged section of siding.

Fading: Fading is a common problem, particularly with vinyl siding. Regular cleaning and the application of a UV protectant can help mitigate fading. Severe fading may require repainting or replacing the affected panels.

Weather Damage: Wind, rain, and hail can all damage siding. Regular inspections and prompt repairs are essential to prevent further damage. Consider installing additional wind barriers or storm shutters in areas prone to severe weather.

Siding Maintenance Schedule

| Task | Frequency |

|---|---|

| Clean siding with water and a soft brush | Twice yearly (spring and fall) |

| Inspect siding for damage (cracks, holes, etc.) | Twice yearly (spring and fall) |

| Repair minor damage (caulk small cracks) | As needed |

| Clean gutters and downspouts | Twice yearly (spring and fall) |

| Inspect for signs of pest infestation | Annually |

| Consider professional inspection and cleaning | Every 5-7 years |

Aesthetic Considerations and Design Choices

Source: buildingproductadvisor.com

Choosing the right siding for your manufactured home goes beyond just protection from the elements; it significantly impacts your home’s curb appeal and overall aesthetic. The color, texture, and style of your siding can dramatically transform the look and feel of your property, increasing its value and making it a more welcoming and attractive place to live. Careful consideration of these aesthetic factors will ensure your home reflects your personal style and enhances its surroundings.

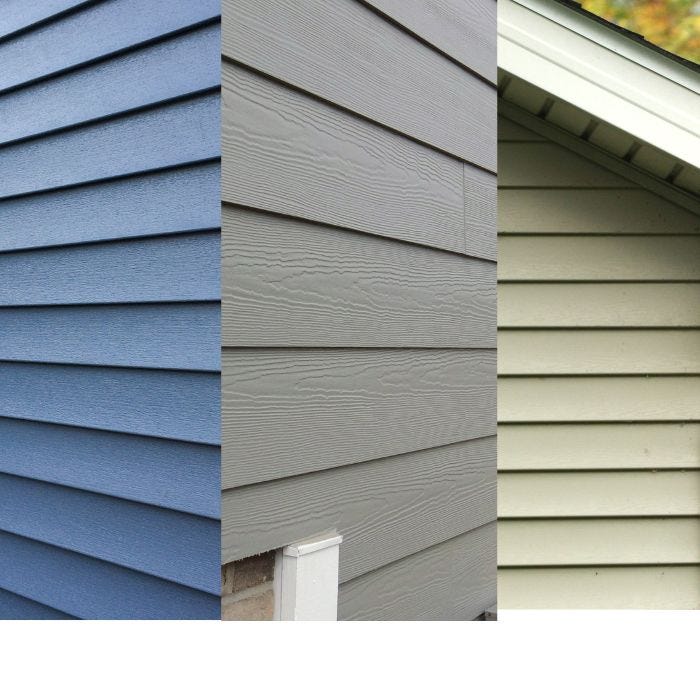

Different siding colors and textures create distinct visual effects. Light colors, such as whites, creams, and pastels, can make a home appear larger and brighter, especially in sunny climates. They also reflect more heat, potentially reducing cooling costs. Darker colors, like grays, browns, and blues, can create a more dramatic and sophisticated look, but they absorb more heat and may require more frequent cleaning. The texture of the siding also plays a crucial role. Smooth siding offers a clean, modern look, while textured siding, such as clapboard or shingle, provides a more rustic or traditional feel. The interplay of color and texture allows for a wide range of design possibilities.

Siding Color Palettes and Their Effects

Color selection is paramount in achieving the desired aesthetic. A cool color palette, using blues, greens, and grays, creates a calming and serene atmosphere, often suitable for homes nestled in wooded areas or near water. Warm color palettes, featuring browns, reds, and yellows, evoke a sense of coziness and warmth, ideal for homes in more rural or suburban settings. Neutral color palettes, relying on whites, creams, and beiges, provide a versatile backdrop that allows other architectural features to stand out. Consider the surrounding landscape and the overall style of your neighborhood when choosing a color palette. For instance, a home in a desert environment might benefit from earth tones, while a coastal home might look best with blues and whites.

Coordinating Siding with Architectural Features

Effective siding choices harmonize with other architectural elements. The siding should complement, not clash with, the roof, windows, and trim. For example, a home with a dark brown roof might look stunning with beige or light brown siding, while a lighter gray roof might pair well with white or light gray siding. Consider using contrasting trim colors to add visual interest and highlight architectural details. Darker trim against lighter siding, or vice versa, can create a striking effect. Window styles also influence siding selection; larger, more modern windows might pair well with sleek, contemporary siding, while smaller, more traditional windows might complement more rustic siding options.

Siding Design Schemes for Manufactured Homes

Below are three distinct siding design schemes illustrating the versatility of siding in creating diverse aesthetics for manufactured homes.

Traditional Siding Design

This design emphasizes classic elegance. The siding material would be vinyl clapboard in a warm, creamy white. The texture would be slightly textured to mimic real wood clapboard. The trim would be a deep, charcoal gray, providing a crisp contrast against the lighter siding. The roof would be a dark gray asphalt shingle. This scheme creates a timeless and sophisticated look, suitable for a variety of settings.

Modern Siding Design

This design showcases a clean, minimalist aesthetic. The siding would be fiber cement panels in a smooth, light gray finish. The lack of texture emphasizes the modern, sleek lines of the home. The trim would be a matching light gray, or perhaps a slightly darker gray for subtle contrast. The roof would be a flat, dark gray metal roof. This scheme creates a contemporary and sophisticated look, ideal for urban or suburban settings.

Rustic Siding Design

This design evokes a sense of warmth and natural charm. The siding would be cedar shingles in a natural, weathered gray. The texture of the shingles would be prominent, adding to the rustic feel. The trim would be a dark brown, complementing the natural tones of the shingles. The roof would be a dark brown asphalt shingle. This scheme creates a cozy and inviting atmosphere, perfect for homes in rural or wooded areas.

Environmental Impact and Sustainability

Source: com.au

Choosing siding for your manufactured home involves considering more than just aesthetics and cost; the environmental impact of your selection plays a significant role in the long-term sustainability of your home and the planet. Different materials have varying environmental footprints, impacting everything from resource depletion to pollution during manufacturing and disposal.

Understanding the life cycle of siding materials—from raw material extraction to manufacturing, installation, use, and eventual disposal—is crucial for making an informed, eco-conscious choice. This section will explore the environmental implications of various siding options and highlight sustainable alternatives.

Manufacturing Processes and Energy Consumption

The manufacturing process of different siding materials significantly influences their environmental impact. For instance, vinyl siding, while widely popular due to its affordability and low maintenance, is a petroleum-based product. Its production consumes considerable energy and releases greenhouse gases. Conversely, fiber cement siding, though more energy-intensive to produce initially, often boasts a longer lifespan, reducing the need for frequent replacements and thus minimizing its overall environmental impact over time. Wood siding, sourced from sustainably managed forests, can be a relatively environmentally friendly option, but its carbon footprint depends heavily on the forestry practices employed. Metal sidings, like aluminum and steel, require significant energy input during manufacturing but are highly durable and recyclable. The energy intensity of each manufacturing process should be weighed against the material’s lifespan and recyclability.

Recyclability and End-of-Life Management, Best siding for manufactured home

The end-of-life management of siding materials is another crucial aspect of their environmental impact. Some materials, like vinyl, are notoriously difficult to recycle, often ending up in landfills. Others, such as aluminum and steel siding, are readily recyclable and can be melted down and reused in new products. Wood siding, depending on its condition, might be repurposed or used for biomass energy. Fiber cement siding presents recycling challenges due to its composite nature, although some components can be recovered. Considering the recyclability of a material significantly reduces its environmental footprint by diverting waste from landfills and conserving resources.

Sustainable and Eco-Friendly Siding Options

Several siding options are specifically designed with sustainability in mind. Recycled materials are increasingly incorporated into siding production, reducing reliance on virgin resources. For example, some vinyl siding manufacturers now use recycled PVC content. Bamboo siding, a rapidly renewable resource, offers a sustainable alternative to traditional wood. Additionally, manufacturers are exploring the use of bio-based polymers and other innovative materials with lower environmental impacts. Choosing these sustainable options directly contributes to reducing your home’s overall environmental footprint.

Long-Term Environmental Benefits of Durable Siding

Investing in durable, low-maintenance siding offers significant long-term environmental benefits. A longer-lasting siding material reduces the need for frequent replacements, minimizing the environmental impact associated with manufacturing, transportation, and disposal. This translates to less energy consumption, reduced waste generation, and lower greenhouse gas emissions over the siding’s lifespan. For instance, a high-quality fiber cement siding, while initially more expensive, may last for decades, significantly reducing its overall environmental footprint compared to a less durable option that needs replacing every few years.

Final Thoughts

Selecting the best siding for your manufactured home is a significant investment that impacts both its appearance and lifespan. By carefully weighing the factors discussed—material properties, climate considerations, budget constraints, and aesthetic preferences—you can make a confident decision. Remember, proper installation and regular maintenance are crucial for maximizing the lifespan of your chosen siding. With the right information and planning, you can transform your manufactured home’s exterior into a beautiful and durable showcase of your personal style.

FAQ Guide

What is the average lifespan of vinyl siding?

Vinyl siding typically lasts 20-30 years, depending on quality and maintenance.

Can I install siding myself on a manufactured home?

While possible for some types, professional installation is often recommended, especially for complex designs or less common materials. Improper installation can void warranties.

How often should I clean my siding?

Cleaning frequency depends on the material and your climate. Generally, at least once a year is recommended, using a gentle cleaner and soft brush.

What are the common signs of siding damage that need immediate attention?

Look for cracks, significant fading, loose or damaged panels, and water damage. Address these issues promptly to prevent further deterioration.

Are there any building codes specific to siding on manufactured homes?

Yes, local building codes vary. Check with your local authority for specific requirements before starting any work.