Cement Siding Contractors Your Guide

Cement siding contractors are essential for homeowners looking to upgrade their exterior with a durable and stylish option. This guide explores everything from understanding the cement siding market and finding reputable contractors to the installation process, maintenance, and crucial safety considerations. We’ll delve into the advantages and disadvantages of cement siding compared to other materials, helping you make an informed decision for your home improvement project.

Choosing the right contractor is paramount. We’ll provide a comprehensive checklist to help you evaluate potential contractors, ensuring you select a qualified and experienced professional for your project. We’ll also walk you through the installation process, offering insights into proper preparation, installation methods, and potential challenges to expect along the way. Finally, we’ll cover maintenance, repairs, and the necessary legal and safety precautions to guarantee a successful and long-lasting outcome.

Understanding the Cement Siding Market

Cement siding, a durable and low-maintenance exterior cladding option, is experiencing a surge in popularity. This section explores current trends, advantages and disadvantages, cost breakdowns, and design styles within the cement siding market. Understanding these factors is crucial for contractors seeking to effectively serve their clients and remain competitive.

Current Trends in Cement Siding Installation

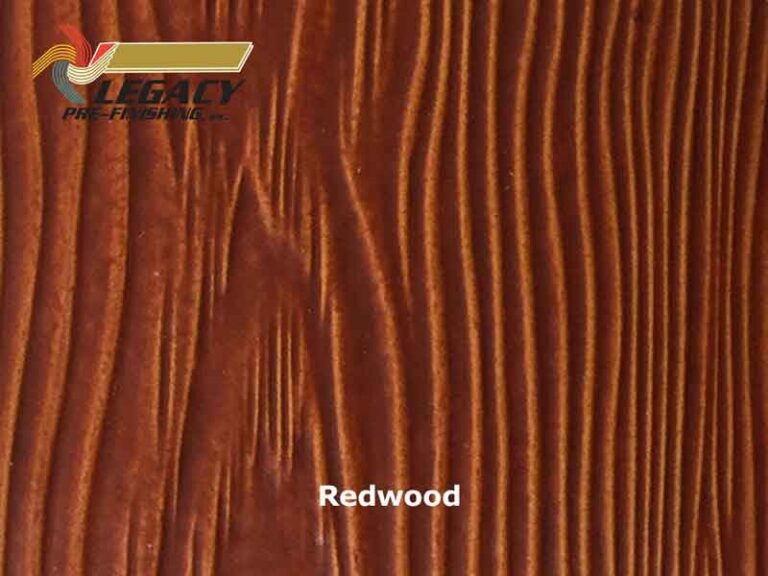

The cement siding market shows a strong preference for larger format panels, simplifying installation and reducing visible seams. Color choices are trending toward earth tones and muted shades, reflecting a move towards more natural and understated aesthetics. Furthermore, there’s increasing demand for textured finishes that mimic natural materials like wood or stone, offering a more visually appealing alternative to traditional smooth cement board. Finally, integration with smart home technology, such as the incorporation of sensors for monitoring building conditions, is slowly emerging as a niche but growing trend.

Advantages and Disadvantages of Cement Siding

Cement siding offers several key advantages. Its exceptional durability makes it highly resistant to damage from impact, fire, insects, and rot, resulting in a longer lifespan compared to other materials. It’s also incredibly low-maintenance, requiring minimal cleaning and upkeep. Furthermore, cement siding is highly resistant to fading and discoloration from sun exposure. However, it’s heavier than other siding options, potentially requiring more robust structural support. Installation can be more complex and time-consuming than vinyl or wood siding, requiring specialized tools and expertise. Finally, cement siding can be more expensive upfront than some alternatives.

Cost Breakdown of Cement Siding Installation

The cost of cement siding installation varies significantly based on several factors. The size of the project is a primary driver, with larger homes naturally incurring higher costs. The chosen style and design of the siding also plays a role; intricate designs and specialized finishes will add to the overall expense. Labor costs are a substantial component, varying based on regional wages and contractor experience. Material costs are also influenced by the type of cement board, its thickness, and the desired finish. A typical cost range, including materials and labor, might fall between $8 and $15 per square foot, but this can fluctuate significantly. For example, a 1,500 square foot home might cost between $12,000 and $22,500. This is a rough estimate and should be confirmed with local contractors for accurate pricing.

Cement Siding Styles and Designs, Cement siding contractors

Cement siding offers a surprising diversity of styles and designs. Many manufacturers offer panels that mimic the look of wood clapboard, providing a classic and aesthetically pleasing option. Other styles replicate the appearance of natural stone, offering a more rustic and textured finish. Some manufacturers even offer panels with embossed patterns or detailed textures, adding visual interest and depth. Color options are extensive, ranging from traditional earth tones to vibrant and contemporary shades. For instance, a home could feature a traditional clapboard style in a muted grey, while another might opt for a modern, sleek design in a deep charcoal. The variety allows for customization to match virtually any architectural style.

Finding and Vetting Contractors

Source: unitedhomeexperts.com

Choosing the right contractor for your cement siding project is crucial for a successful and long-lasting outcome. A thorough vetting process will protect your investment and ensure a smooth installation. This section will guide you through finding and evaluating reputable cement siding contractors in your area.

Finding qualified contractors requires a multi-pronged approach. Start by leveraging online resources such as online review sites, contractor directories, and your local Better Business Bureau. Networking with friends, family, and neighbors who have recently had similar work done can also yield valuable recommendations. Finally, attending local home improvement shows or contacting your local building supply stores can provide additional leads. Remember to always verify the information you find online with additional sources.

Contractor Qualification Criteria

Evaluating contractor qualifications involves examining several key aspects. Licensing ensures the contractor adheres to industry standards and possesses the necessary expertise. Verifying licensing information can usually be done through your state’s contractor licensing board website. Adequate insurance, including general liability and workers’ compensation, protects you from potential financial liabilities in case of accidents or damages during the project. Finally, a strong track record, evidenced by years of experience and positive client reviews, indicates a contractor’s reliability and skill. Requesting references and checking online reviews are essential steps in this process. Look for contractors with a consistent history of positive feedback and a demonstrated understanding of cement siding installation.

Questions to Ask Potential Contractors

Before committing to a contractor, a comprehensive list of questions should be asked to clarify expectations and ensure a transparent working relationship. This includes questions about their experience with cement siding, the specific materials they use, their project timeline, their payment terms, their warranty offerings, and their process for handling potential issues or delays. Asking for detailed information about their permits and insurance policies also ensures that they are operating legally and responsibly. Inquire about their cleanup procedures at the end of the project, and ask for a detailed breakdown of the total cost, including labor and materials. Don’t hesitate to ask for examples of previous projects and contact information for references.

Contractor Bidding Processes and Contract Terms

Contractors typically employ different bidding processes, such as fixed-price bids, unit-price bids, or cost-plus bids. A fixed-price bid provides a set price for the entire project, offering predictability and budget control. A unit-price bid involves pricing each element of the project separately, which is beneficial for larger or more complex projects where scope changes are possible. A cost-plus bid involves reimbursing the contractor for actual costs plus a markup for profit, offering flexibility but potentially lacking budget certainty. The contract should clearly Artikel the scope of work, payment schedule, project timeline, warranty information, dispute resolution mechanisms, and the responsibilities of both parties. Review the contract carefully before signing, and seek legal advice if necessary. A well-written contract will protect both the homeowner and the contractor, ensuring a clear understanding of expectations and responsibilities.

The Installation Process: Cement Siding Contractors

Source: prosuperiorconstruction.com

Cement siding installation is a multi-step process requiring precision and expertise to ensure a durable and aesthetically pleasing finish. Proper preparation is crucial for a successful outcome, minimizing the risk of future problems and maximizing the lifespan of your siding. The process generally involves several key stages, from initial site preparation to final cleanup.

Successful cement siding installation hinges on thorough preparation and meticulous execution of each step. Neglecting any stage can compromise the overall quality, longevity, and aesthetic appeal of the finished product. Understanding the process, therefore, is key to choosing the right contractor and ensuring a high-quality installation.

Surface Preparation and Treatment

Before any siding is installed, the existing surface must be thoroughly prepared. This involves removing old siding, cleaning the wall surface to remove dirt, loose paint, and debris, and repairing any damage such as cracks or holes. The surface should be even and dry before installation begins. Priming the surface is also a crucial step, providing a better bond for the cement siding and enhancing its overall adhesion and longevity. Ignoring this preparation phase can lead to issues like poor adhesion, cracking, and premature deterioration of the siding. For example, failing to address moisture issues in the wall before installation can lead to mold growth behind the siding, significantly impacting the building’s structure and health.

Installation Methods

There are several methods for installing cement siding, each with its own advantages and disadvantages. The most common methods include nailing, screwing, and using a combination of both.

The choice of method depends on factors such as the type of siding, the substrate, and the climate. For instance, nailing is a faster and often less expensive method, but it can be less secure in certain conditions, such as areas with high winds. Screwing, while more time-consuming and potentially more expensive, offers superior hold and resistance to high winds and other environmental stresses. A combination approach, using both nails and screws, is often employed for optimal security and longevity.

A Visual Representation of the Installation Process

Imagine a wall needing new cement siding. First, the old siding is removed, revealing the underlying structure. Next, the wall is thoroughly cleaned and any damage is repaired. A primer is applied to prepare the surface for the new siding. Then, the cement siding panels are installed, starting from the bottom and working upwards, each panel carefully aligned and secured using either nails, screws, or a combination of both. Each panel is overlapped to ensure a weathertight seal. Finally, trim pieces are installed around windows, doors, and corners, completing the installation. The entire process requires careful attention to detail and adherence to manufacturer’s instructions.

Maintenance and Repair

Source: hw.net

Cement siding, while incredibly durable, still requires regular maintenance to ensure its longevity and attractive appearance. Neglecting this can lead to costly repairs down the line. A proactive approach will protect your investment and keep your home looking its best for years to come.

Cement Siding Maintenance Schedule

A consistent maintenance schedule is key to preventing significant problems. This should include both regular cleaning and thorough inspections. A yearly inspection and cleaning is generally sufficient, but more frequent attention may be needed in harsh climates or areas with heavy pollution.

Yearly Inspection: Carefully examine all siding surfaces for cracks, chips, loose or damaged pieces, staining, or signs of moisture penetration. Pay close attention to areas around windows, doors, and corners, as these are often more vulnerable. Document any issues found and prioritize repairs.

Cleaning: Use a pressure washer set to a low pressure setting to avoid damaging the siding. Start from the bottom and work your way up, overlapping each pass to ensure complete coverage. For stubborn stains, a solution of mild detergent and water can be applied before rinsing. Avoid using abrasive cleaners or harsh chemicals, as these can scratch or dull the surface. After cleaning, allow the siding to dry completely.

Common Issues and Solutions

Several problems can affect cement siding, but many are easily addressed with timely intervention.

Cracks and Chips: Small cracks and chips can often be repaired with a cement patching compound matched to the siding’s color. Larger damage may require professional repair or replacement of the affected panel.

Staining: Algae, mildew, and other stains can be removed with a pressure washer and a mild detergent solution. Persistent stains might necessitate the use of a specialized siding cleaner. Preventing staining is best achieved through regular cleaning.

Moisture Penetration: Water damage can lead to serious structural problems. Regular inspections for signs of moisture, such as discoloration or bubbling paint, are crucial. Addressing leaks promptly is essential to prevent further damage. Proper caulking around windows and doors is a key preventative measure.

Preventative Measures

Taking proactive steps can significantly extend the life of your cement siding.

Regular Cleaning: Consistent cleaning prevents the buildup of dirt, grime, and organic matter that can lead to staining and damage.

Proper Caulking: Regularly inspect and re-caulk around windows, doors, and other areas where the siding meets other building materials. This prevents water from seeping behind the siding.

Trim Maintenance: Keep the trim around your windows and doors in good repair. Damaged trim can allow water to penetrate the siding.

Gutter Maintenance: Ensure gutters and downspouts are clean and functioning properly to divert water away from the foundation and siding.

Maintenance Comparison Table

| Siding Material | Cleaning Frequency | Repair Frequency | Maintenance Difficulty |

|---|---|---|---|

| Cement | Annual | Infrequent (for major damage) | Low to Moderate |

| Vinyl | Annual (or as needed) | Infrequent (for major damage) | Low |

| Wood | Semi-annual to Annual (depending on climate) | Frequent (painting, staining, repairs) | High |

Legal and Safety Considerations

Source: blueridgeexteriors.com

Cement siding installation, while offering a durable and aesthetically pleasing exterior, requires careful adherence to legal regulations and stringent safety protocols to ensure a successful and hazard-free project. Ignoring these aspects can lead to legal repercussions, project delays, and potentially serious injuries. This section details the necessary permits, identifies potential hazards, and Artikels safety precautions to maintain a safe and compliant work environment.

Permitting and Regulations

Before commencing any cement siding installation, contractors must obtain the necessary permits from local authorities. These permits vary depending on location and project scope. Typically, a building permit is required, which often involves submitting detailed plans and specifications to the relevant building department for review and approval. This process ensures the project complies with local building codes and zoning regulations. Contractors should familiarize themselves with the specific requirements of their jurisdiction well in advance to avoid delays. Failure to obtain the necessary permits can result in fines, stop-work orders, and even legal action. Some areas may also require additional permits related to waste disposal or work near power lines. It is crucial to check with local authorities for a comprehensive list of required permits and associated documentation.

Safety Hazards and Mitigation Strategies

Cement siding installation presents several potential safety hazards. Working at heights is inherent in the process, posing a risk of falls. The use of power tools, such as saws and nail guns, introduces the risk of lacerations, amputations, and eye injuries. The materials themselves, particularly cement boards, are heavy and can cause back injuries if handled improperly. Exposure to dust and other airborne particles can lead to respiratory problems. Furthermore, working with ladders and scaffolding necessitates careful setup and adherence to safe practices.

Mitigation strategies include the use of appropriate personal protective equipment (PPE), such as hard hats, safety glasses, gloves, and respirators. Proper scaffolding and fall protection systems, including harnesses and safety nets, are essential when working at heights. Power tools should be maintained regularly and operated according to manufacturer instructions. Workers should be trained in the safe handling of materials and the proper use of equipment. Regular safety meetings and site inspections can help identify and address potential hazards proactively. Implementing a comprehensive safety plan, reviewed and approved by a safety professional, is highly recommended for larger projects.

Adherence to Building Codes and Safety Standards

Strict adherence to building codes and safety standards is paramount throughout the entire cement siding installation process. These codes provide minimum requirements for construction, ensuring structural integrity, fire safety, and overall building performance. Compliance is not only a legal obligation but also crucial for the longevity and safety of the structure. Deviations from building codes can lead to structural instability, increased risk of damage, and potential liability issues for the contractor. Regular inspections by qualified professionals can help ensure adherence to these standards throughout the project. Using certified materials and employing qualified and experienced installers further contribute to a safe and compliant installation.

Safety Precautions for Contractors

Before beginning any work, contractors should conduct a thorough site survey to identify potential hazards. This includes checking for overhead power lines, underground utilities, and any other obstacles. Here’s a list of safety precautions contractors should take:

- Always use appropriate personal protective equipment (PPE), including hard hats, safety glasses, gloves, and respirators.

- Properly erect and secure scaffolding or ladders, ensuring they are stable and able to support the weight of workers and materials.

- Use appropriate fall protection systems, such as harnesses and safety nets, when working at heights.

- Handle cement boards and other materials carefully to prevent back injuries. Use mechanical lifting devices when possible.

- Regularly inspect and maintain power tools to ensure they are in safe working order.

- Follow manufacturer’s instructions for the use of all equipment and materials.

- Implement a system for proper waste disposal to minimize environmental impact.

- Conduct regular safety meetings to review procedures and address potential hazards.

- Report all accidents and injuries immediately.

- Ensure all workers receive appropriate safety training before starting work.

Final Wrap-Up

Investing in cement siding is a significant home improvement decision, and selecting the right contractor is crucial for a successful project. By understanding the market trends, carefully vetting potential contractors, and following proper installation and maintenance practices, you can enjoy the long-lasting beauty and durability of cement siding for years to come. Remember to prioritize safety and always adhere to building codes and regulations throughout the process. With thorough planning and the right professional, your cement siding project will enhance your home’s curb appeal and increase its value.

Commonly Asked Questions

What is the average lifespan of cement siding?

With proper maintenance, cement siding can last 50 years or more.

Can I install cement siding myself?

While possible, it’s generally recommended to hire professionals due to the complexity and physical demands of the job. Improper installation can lead to damage and costly repairs.

How much does cement siding cost per square foot?

The cost varies significantly based on location, contractor, and chosen style. It’s best to get multiple quotes from reputable contractors.

Does cement siding require special cleaning products?

Generally, a simple pressure washing is sufficient. Avoid abrasive cleaners that could damage the surface.

What are the common problems with cement siding?

Cracking, chipping, and fading are potential issues, often preventable with proper installation and maintenance.