Hardie Plank Installation Cost A Comprehensive Guide

Hardie plank installation cost is a significant factor when planning your home exterior renovation. Understanding the various elements that contribute to the final price—from material selection and labor costs to permits and project complexity—is crucial for budgeting effectively. This guide provides a detailed breakdown of costs, offering insights into saving money without compromising quality, helping you navigate the process with confidence.

We’ll explore the key factors influencing the overall expense, including material costs (like the type and quantity of Hardie plank), labor costs (based on installer experience and location), and permit fees. We’ll also compare the costs and risks of DIY versus professional installation, providing practical examples and cost ranges for various project sizes and home types. Learn how to estimate your project costs accurately, identify potential cost-saving strategies, and create a realistic budget.

Factors Influencing Hardie Plank Installation Cost

Source: evodesigninc.com

The cost of installing Hardie Plank siding can vary significantly depending on several key factors. Understanding these factors will help you budget accurately and make informed decisions about your project. This section details the primary influences on the final price, from material selection to labor costs and associated fees.

Material Costs, Hardie plank installation cost

The type and quantity of Hardie Plank siding you choose directly impact the overall material cost. Different Hardie Plank products, such as lap siding, shingles, or vertical planks, have varying price points per square foot. The size of your house and the complexity of the design (e.g., many corners, dormers) will determine the amount of material needed. For example, a large, multi-story home with intricate architectural details will require substantially more Hardie Plank than a small, single-story house with a simple design. Higher-end finishes, such as those with textured surfaces or specific colors, will generally be more expensive than standard options. Remember to factor in additional materials such as trim pieces, fasteners, and underlayment.

Labor Costs

Labor costs represent a significant portion of the total installation expense. The experience level of the installer directly affects the price; experienced professionals command higher rates due to their expertise and efficiency. Geographic location also plays a crucial role. Labor costs in high-demand areas or regions with a high cost of living tend to be higher than in less populated areas. Project complexity significantly influences labor time and therefore cost. Intricate designs, extensive trim work, or difficult-to-access areas will increase the labor hours required, leading to a higher overall cost. For example, a house with many angles and complex trim work will require more time and skill, thus increasing labor costs.

Permits and Associated Fees

Obtaining the necessary building permits is a crucial step in any home improvement project. Permit fees vary widely depending on your location and the scope of the project. Other associated fees, such as waste disposal fees for removing old siding, may also add to the total cost. It’s essential to budget for these fees upfront to avoid unexpected expenses. The exact costs should be confirmed with your local building department.

DIY vs. Professional Installation

Choosing between DIY installation and hiring a professional contractor involves a trade-off between cost, time commitment, and risk.

| DIY Installation | Professional Installation | |

|---|---|---|

| Cost Breakdown | Lower initial material cost, but potential for added costs due to mistakes or material waste. | Higher initial cost, including labor and potentially higher material costs due to professional sourcing. |

| Time Commitment | Significantly longer project duration, dependent on experience and available time. | Shorter project duration, with work completed by experienced professionals within a reasonable timeframe. |

| Risk Factors | Higher risk of mistakes, damage to property, and potential safety hazards. May void warranties if not installed correctly. | Lower risk due to professional expertise and adherence to building codes. Typically includes warranties on workmanship. |

Breakdown of Hardie Plank Installation Costs

Source: advanceroofingllc.com

Understanding the cost of Hardie Plank installation is crucial for effective budgeting. This breakdown provides a detailed look at the expenses involved, helping you accurately estimate the total project cost. Remember that these are estimates, and actual costs can vary based on location, project complexity, and contractor choices.

Material Procurement Costs

This section details the expenses associated with acquiring the necessary Hardie Plank siding materials. The cost of materials is a significant portion of the overall project budget. Factors influencing material costs include the type of Hardie Plank chosen (e.g., lap siding, panel siding, different colors and textures), the quantity needed, and any additional trim or accessories.

| Cost Item | Description | Estimated Cost (Range) | Notes |

|---|---|---|---|

| Hardie Plank Siding | The primary siding material. | $2 – $6 per square foot | Cost varies based on type, color, and quantity. |

| Trim and Accessories | J-channels, corner boards, flashing, etc. | $1 – $3 per linear foot | The amount of trim needed depends on the project’s complexity. |

| Fasteners and Sealants | Nails, screws, caulk, etc. | $0.50 – $1.50 per square foot | These are essential for proper installation and weather protection. |

Preparation Costs

Before installation can begin, the existing siding must be removed, and the underlying structure prepared. This involves labor costs for demolition, repairs to the sheathing (if needed), and surface preparation.

| Cost Item | Description | Estimated Cost (Range) | Notes |

|---|---|---|---|

| Existing Siding Removal | Removal of old siding, if applicable. | $1 – $3 per square foot | This cost is omitted if installing over new sheathing. |

| Sheathing Repairs | Repairing any damaged areas of the house’s sheathing. | Varies greatly depending on the extent of repairs. | This could range from minimal to very significant costs. |

| Surface Preparation | Cleaning, priming, and other prep work. | $0.50 – $1.50 per square foot | Proper preparation is crucial for a long-lasting finish. |

Installation Costs

This is the largest cost component, encompassing the labor involved in installing the Hardie Plank siding and associated trim. The cost depends heavily on the project’s size and complexity, as well as the contractor’s hourly rate.

| Cost Item | Description | Estimated Cost (Range) | Notes |

|---|---|---|---|

| Labor Costs | Cost of the installation crew’s time and expertise. | $3 – $8 per square foot | More complex designs or difficult access will increase this cost. |

Cleanup Costs

After installation, the worksite needs to be cleaned up, removing debris and ensuring a tidy finish. While seemingly minor, these costs should be factored into the overall budget.

| Cost Item | Description | Estimated Cost (Range) | Notes |

|---|---|---|---|

| Waste Removal | Disposal of old siding, packaging, and other debris. | $100 – $500 | This depends on the amount of waste generated. |

| Site Cleanup | Cleaning and tidying the work area. | $50 – $200 | Ensures a clean and safe environment after completion. |

Sample Budget for a Typical Hardie Plank Siding Installation

Let’s consider a medium-sized, single-story house with approximately 1500 square feet of siding.

| Cost Item | Estimated Cost |

|---|---|

| Materials | $4500 – $9000 |

| Preparation | $1500 – $4500 |

| Installation | $4500 – $12000 |

| Cleanup | $150 – $700 |

| Total Estimated Cost | $10650 – $26200 |

Estimating Hardie Plank Installation Costs

Source: thespruce.com

Accurately estimating the cost of Hardie Plank installation is crucial for both homeowners and contractors. A well-defined estimate ensures the project stays within budget and avoids unexpected financial surprises. This section Artikels methods for creating a comprehensive cost estimate, covering materials, labor, and contingency planning.

Material Cost Calculation

Calculating material costs involves determining the total square footage of siding needed and multiplying it by the price per square foot. Begin by accurately measuring the area to be sided. Remember to account for windows, doors, and other openings, subtracting their area from the total wall surface area. Next, determine the cost per square foot of Hardie Plank siding, including any necessary trim pieces and fasteners. This price will vary based on the chosen style, color, and retailer. Finally, multiply the total square footage by the cost per square foot to arrive at the total material cost. For example, if you need 500 square feet of siding at $6 per square foot, the material cost would be $3000. Don’t forget to add sales tax to this figure.

Labor Cost Estimation

Estimating labor costs requires considering the project’s complexity and the contractor’s hourly or daily rate. Simple projects with minimal preparation work will require less labor than complex installations involving extensive cutting, fitting around intricate features, or significant repairs to the underlying structure. Obtain quotes from multiple contractors, comparing their rates and experience. A detailed breakdown of labor costs should be included in the contractor’s estimate, clarifying the hours allocated to each stage of the installation (preparation, installation, cleanup). For instance, a contractor might charge $50 per hour and estimate 20 hours of labor for a medium-sized project, resulting in a labor cost of $1000.

Step-by-Step Guide for Total Cost Estimation

To calculate the total estimated cost, follow these steps:

- Measure the area: Accurately measure the total square footage of the area requiring Hardie Plank siding.

- Calculate material costs: Determine the cost per square foot of Hardie Plank and multiply it by the total square footage. Add the cost of trim, fasteners, and any other necessary materials.

- Estimate labor costs: Obtain quotes from multiple contractors and choose a rate that aligns with your budget and project needs. Factor in the estimated labor hours.

- Calculate contingency: Add a contingency of 10-20% to cover unexpected expenses, such as material damage, unforeseen repairs, or additional labor. This percentage can be adjusted based on the project’s complexity and potential risks.

- Calculate total estimated cost: Sum the material costs, labor costs, and contingency to arrive at the total estimated cost. For example, if material costs are $3000, labor costs are $1000, and contingency is $400 (10% of $4000), the total estimated cost would be $4400.

Total Estimated Cost = Material Costs + Labor Costs + Contingency

Saving Money on Hardie Plank Installation

Installing Hardie Plank siding can significantly enhance your home’s curb appeal and longevity, but the costs can be substantial. However, with careful planning and strategic choices, you can effectively minimize expenses without sacrificing quality. This section Artikels several methods to achieve significant savings on your Hardie Plank installation project.

Choosing Cost-Effective Hardie Plank Options

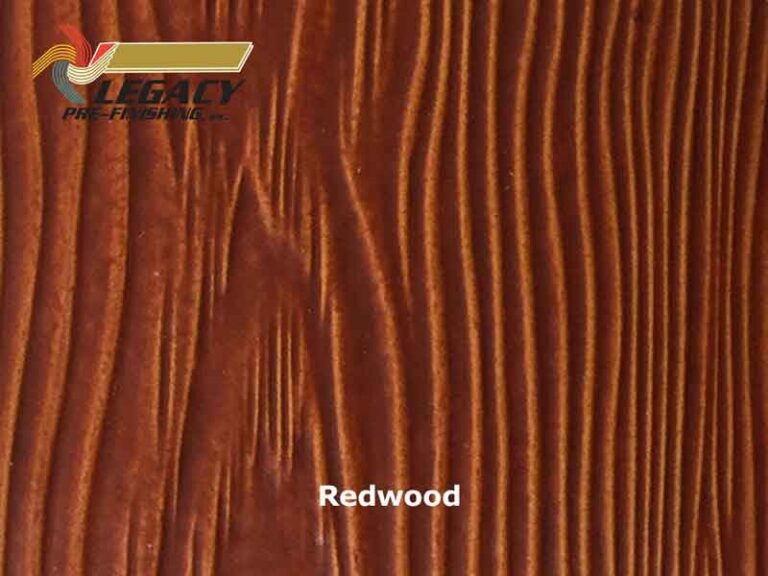

Hardie Plank offers a range of products, each with varying price points. Selecting a less expensive option, such as standard lap siding instead of more intricate designs like vertical planks or shingles, can lead to considerable savings. Consider the overall aesthetic you desire and weigh the cost difference against the visual impact. For example, the standard HardiePlank lap siding is generally more affordable than the HardieShingle or HardiePanel products. The color you choose can also impact the price; solid colors are often less expensive than custom-mixed or more complex shades.

Negotiating with Contractors and Preparing the Site

Contractor costs often represent a significant portion of the total project expense. Obtaining multiple bids from reputable contractors allows for comparison and negotiation. Clearly outlining the scope of work, including all materials and labor, ensures transparency and prevents unexpected cost increases. Furthermore, preparing the site beforehand can reduce labor time and, consequently, labor costs. This includes removing existing siding, clearing debris, and ensuring easy access for workers and materials. A well-prepared site can translate to a discount or reduced hourly rate from your contractor. For example, if you remove the old siding yourself, you can significantly reduce the overall labor cost.

Cost-Saving Measures During Installation

Careful planning during the installation phase can also yield savings. For example, minimizing waste by accurately measuring and cutting materials reduces material costs. Efficient material handling and organization on-site minimize delays and improve the overall efficiency of the installation process. This might involve creating a staging area for materials to keep things organized and easily accessible. Efficient work practices by the contractor will also help to minimize labor costs. For instance, experienced installers work faster and more accurately, resulting in less material waste and fewer labor hours.

Cost-Effective Solutions for Specific Aspects of Installation

Several specific aspects of the installation offer opportunities for cost reduction. For example, using readily available, standard-size trim pieces instead of custom-made ones can save money. Similarly, opting for a simpler flashing system or using readily available flashing materials can also reduce costs. Using readily available, standard fasteners instead of specialized or premium ones can also be a cost-effective solution. You can also consider painting the siding yourself instead of hiring a professional painter; this can significantly reduce the labor costs. However, ensure you have the necessary skills and equipment to achieve a professional finish. If not, the cost savings could be negated by poor workmanship.

Visual Representation of Hardie Plank Installation Costs

Understanding the cost breakdown of a Hardie Plank siding installation is crucial for budgeting and planning. A visual representation can greatly simplify this complex process, making it easier to grasp the relative contributions of different factors to the overall expense. This section will describe a typical project and provide a detailed description for a graphic illustrating the cost breakdown.

A typical Hardie Plank installation project involves several key stages. First, the existing siding (if any) needs to be removed and disposed of properly. Next, the underlying sheathing is inspected for damage and repaired as needed. This might involve replacing rotten wood or addressing any structural issues. Then, water-resistant barrier is installed, followed by the installation of the Hardie Plank siding itself, which includes cutting, fitting, and nailing each plank precisely. Finally, caulk is applied to seal any gaps and trim is installed to finish the edges. The entire process requires specialized tools, including nail guns, measuring tapes, saws, and levels. Labor costs are a significant component, as skilled professionals are needed to ensure a quality, long-lasting installation.

Hardie Plank Installation Cost Breakdown Graphic

The graphic should be a pie chart showing the percentage breakdown of costs for a typical Hardie Plank siding installation. The pie chart should be visually appealing and easy to understand, using distinct colors for each segment. The chart will have three main segments representing: Materials, Labor, and Permits. Each segment will be clearly labeled with its percentage and dollar amount.

The “Materials” segment will be the largest, representing approximately 40-50% of the total cost. This segment should be further subdivided into smaller pie slices to show the relative costs of different materials: Hardie Plank siding itself (the largest slice within “Materials”), fasteners (nails, screws), underlayment (house wrap), caulk, and trim. Each of these smaller slices should be labeled with its percentage and dollar amount, for example, “Hardie Plank: 60% ($X)”, “Fasteners: 10% ($Y)”, etc. The dollar amounts will need to be adjusted based on the project size and material costs.

The “Labor” segment will represent roughly 40-50% of the total cost, depending on the project complexity and labor rates in the area. This segment should be a single, clearly defined slice of the pie. It should be labeled with its percentage and dollar amount.

The “Permits” segment will be the smallest, representing approximately 5-10% of the total cost. This segment should also be a single slice of the pie. It will be labeled with its percentage and dollar amount.

A key at the bottom of the graphic should provide a legend detailing each segment and its corresponding percentage and dollar amount. The total project cost should be clearly displayed at the bottom as well. For example: “Total Project Cost: $Z”. The graphic should use a professional color palette and font to ensure readability and a clean, professional look. The title of the graphic should be “Hardie Plank Siding Installation Cost Breakdown”. An example project with a total cost of $10,000 might show: Materials (50% – $5000), Labor (45% – $4500), and Permits (5% – $500). The “Materials” segment would then be further broken down as described above.

Epilogue

Source: siding-stcharles.com

Successfully planning your Hardie plank installation hinges on understanding the complete cost picture. By carefully considering material choices, labor rates, permit fees, and potential cost-saving measures, you can create a realistic budget and ensure a smooth, successful project. Remember to always obtain multiple quotes from reputable contractors, factor in unexpected expenses, and prioritize quality workmanship for a long-lasting, beautiful exterior.

Essential FAQs: Hardie Plank Installation Cost

What is the average lifespan of Hardie Plank siding?

Hardie Plank siding is known for its durability and can last 30-50 years or more with proper installation and maintenance.

Does Hardie Plank siding require regular maintenance?

While Hardie Plank is low-maintenance, occasional cleaning (usually with water and a soft brush) is recommended to remove dirt and debris. Inspecting for damage and addressing any issues promptly is also important.

Can I install Hardie Plank siding myself?

While DIY installation is possible, it’s a challenging project requiring specific skills and tools. Hiring a professional is often recommended to ensure proper installation and avoid potential issues.

Are there different warranties for Hardie Plank products?

Yes, James Hardie offers different warranties depending on the specific product and its application. Check the manufacturer’s website for detailed warranty information.

What are the environmental benefits of Hardie Plank siding?

Hardie Plank siding is made from fiber cement, a sustainable material that is resistant to rot, insects, and fire, making it an environmentally friendly option.