Corrugated Fiber Cement Siding A Comprehensive Guide

Corrugated fiber cement siding offers a durable and aesthetically pleasing exterior cladding solution for homes and commercial buildings. This guide delves into the material’s properties, installation process, design considerations, environmental impact, and cost-effectiveness, providing you with the comprehensive information needed to make an informed decision.

From understanding its composition and manufacturing to exploring diverse design options and long-term maintenance, we’ll cover all aspects of corrugated fiber cement siding. We’ll also compare it to other siding materials, helping you weigh the pros and cons to determine if it’s the right choice for your project.

Material Properties of Corrugated Fiber Cement Siding

Source: made-in-china.com

Corrugated fiber cement siding offers a durable and attractive exterior cladding option for homes and commercial buildings. Its strength, longevity, and resistance to various weather conditions make it a popular choice among homeowners and builders. Understanding the material properties of fiber cement siding is crucial for making informed decisions about its suitability for a specific project.

Manufacturing Process of Corrugated Fiber Cement Siding

The manufacturing process begins with mixing Portland cement, cellulose fibers (often recycled paper pulp), silica sand, and other additives like water and potentially pigments for color. This mixture is then formed into sheets using a specialized machine that creates the characteristic corrugated profile. The sheets are then cured under controlled conditions, often involving steam pressure, to achieve optimal strength and durability. Finally, the cured sheets are cut to size and prepared for installation. This process results in a product that is both strong and lightweight, offering a balance of performance and ease of handling.

Composition of Corrugated Fiber Cement Siding

Fiber cement siding primarily consists of Portland cement, which acts as a binder and provides strength. Cellulose fibers, typically recycled wood pulp, are incorporated to enhance the material’s tensile strength and reduce brittleness. Silica sand is added as a filler material, contributing to the overall strength and stability of the siding. Additives such as water-repellent agents and pigments are also included to improve the siding’s performance and aesthetic appeal. The specific ratios of these components vary depending on the manufacturer and desired properties of the final product. Some manufacturers might use other types of fibers, such as wood fibers, although cellulose remains the most common.

Impact of Different Fiber Types on Siding Properties

The type of fiber used significantly influences the final properties of the fiber cement siding. Cellulose fibers, derived from recycled paper pulp, are widely used due to their readily available nature, cost-effectiveness, and ability to create a strong and flexible composite material. Wood fibers, while potentially offering similar strength benefits, might lead to variations in performance depending on the type of wood and its treatment. The length and treatment of the fibers also impact the resulting strength and durability of the finished product. Generally, longer fibers contribute to improved tensile strength and reduced cracking.

Durability Comparison of Fiber Cement Siding with Other Materials

Fiber cement siding demonstrates superior durability compared to many other siding materials. Unlike vinyl siding, which can become brittle and crack under extreme temperatures or impact, fiber cement offers excellent resistance to damage. It is significantly more durable than wood siding, which is susceptible to rot, insect infestation, and warping. While more expensive upfront, fiber cement siding’s long lifespan and low maintenance requirements often result in long-term cost savings compared to other options requiring frequent repairs or replacements.

Weight, Strength, and Moisture Resistance Comparison of Fiber Cement Siding Brands

| Brand | Weight (lbs/sq ft) | Compressive Strength (psi) | Moisture Absorption (%) |

|---|---|---|---|

| Brand A | 3.5 – 4.5 | 6000 – 8000 | <10 |

| Brand B | 3.0 – 4.0 | 5000 – 7000 | <8 |

| Brand C | 4.0 – 5.0 | 7000 – 9000 | <12 |

*Note: These values are approximate and can vary depending on the specific product and thickness. Always consult the manufacturer’s specifications for accurate data.*

Installation and Maintenance of Corrugated Fiber Cement Siding

Corrugated fiber cement siding offers a durable and attractive exterior cladding option for homes and commercial buildings. Proper installation and regular maintenance are crucial to ensuring its longevity and preserving its aesthetic appeal. This section details the steps involved in installation, best practices for tricky areas, necessary tools and safety precautions, and a comprehensive maintenance plan.

Installation Steps for Corrugated Fiber Cement Siding

Installing corrugated fiber cement siding involves several key steps, from preparing the substrate to securing the final panels. Careful attention to detail at each stage is essential for a successful and long-lasting installation.

- Substrate Preparation: Begin by ensuring the underlying wall sheathing is sound, level, and free from any damage or rot. Any imperfections should be repaired before proceeding.

- Framing and Furring Strips: Install horizontal furring strips over the sheathing to create a consistent and level surface for the siding. This helps maintain even spacing and prevents issues with uneven walls.

- Water-Resistive Barrier: Apply a water-resistant barrier, such as housewrap, over the furring strips to protect the wall from moisture penetration. Overlap the seams and seal them properly.

- Flashing: Install flashing around windows, doors, and other openings to prevent water from seeping behind the siding. Proper flashing is critical for preventing water damage.

- Siding Installation: Starting from the bottom, install the corrugated fiber cement siding panels, ensuring proper overlap and alignment. Use appropriate fasteners and spacing to allow for expansion and contraction.

- Caulking and Sealing: Caulk all seams and joints between panels and around openings to create a watertight seal. Use a high-quality, paintable exterior caulk.

- Finishing: Install trim pieces and accessories as needed to complete the installation. This might include corner pieces, J-channels, and soffit trim.

Cutting and Fitting Around Windows and Doors

Cutting and fitting corrugated fiber cement siding around windows and doors requires precision and careful measurement to ensure a neat and watertight finish. Using the correct tools and techniques is essential for achieving a professional look.

Precise measurements are paramount. Use a sharp utility knife or a circular saw with a fine-tooth blade designed for fiber cement to cut the panels. Always wear appropriate safety equipment, including eye protection and a dust mask. For curved areas, score the panel repeatedly with a utility knife before snapping it to avoid chipping. Utilize pre-fabricated trim pieces whenever possible for a clean and professional finish around windows and doors. Ensure proper flashing is installed before securing the siding to prevent water intrusion.

Tools and Safety Equipment

The safe and efficient installation of corrugated fiber cement siding requires specific tools and safety equipment. Prioritizing safety is essential throughout the entire process.

- Measuring tape

- Level

- Circular saw with fine-tooth blade (for fiber cement)

- Utility knife

- Hammer

- Drill with appropriate bits

- Safety glasses

- Dust mask

- Work gloves

- Hearing protection

Maintenance of Corrugated Fiber Cement Siding

Regular maintenance helps prolong the lifespan and aesthetic appeal of your fiber cement siding. A simple cleaning routine and prompt attention to any damage are key components of a successful maintenance plan.

Cleaning should be performed at least once or twice a year, depending on environmental conditions. Use a garden hose with a nozzle to rinse away dirt and debris. For stubborn stains, a mild detergent solution can be used. Avoid using abrasive cleaners or high-pressure washers, as these can damage the siding’s surface. Inspect the siding regularly for any signs of damage, such as cracks, loose panels, or water damage. Repair or replace any damaged sections promptly to prevent further deterioration. Repainting may be necessary every 5-10 years depending on the climate and paint quality.

Regular Inspection and Maintenance Checklist

A regular inspection checklist ensures that potential problems are identified and addressed promptly, preventing costly repairs in the future.

| Task | Frequency | Details |

|---|---|---|

| Visual inspection for cracks, damage, or loose panels | Annually | Check all sides of the house; pay attention to areas prone to moisture |

| Cleaning with garden hose | Twice yearly (Spring & Fall) | Remove dirt, debris, and cobwebs |

| Caulk inspection and repair | Annually | Check for cracks or gaps in caulk around windows, doors, and seams |

| Paint inspection | Every 5-10 years | Assess paint condition for fading, peeling, or chipping |

| Professional inspection | Every 5 years | A professional can identify potential issues that may be overlooked |

Design and Aesthetic Considerations

Corrugated fiber cement siding offers a surprisingly diverse range of aesthetic options, allowing for significant creative freedom in building design. The material’s inherent texture and the variety of colors and profiles available contribute to its versatility, making it suitable for a wide spectrum of architectural styles and personal preferences. Understanding these design aspects is crucial for achieving the desired look and feel for any project.

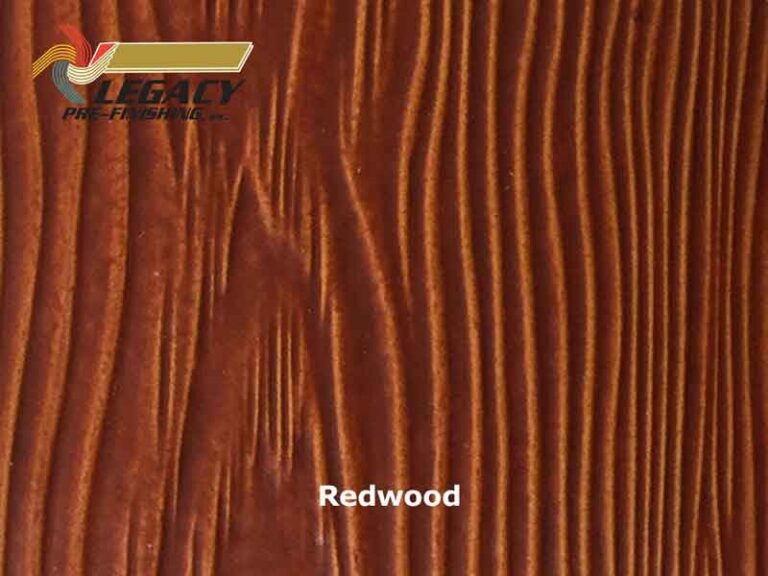

Color and Texture Options

Corrugated fiber cement siding comes in a broad palette of colors, often achieved through a durable, baked-on finish. These colors range from classic neutrals like grays, browns, and creams to bolder shades such as deep blues, greens, and reds. Many manufacturers offer a wide spectrum of colors within specific color families, allowing for subtle variations to complement various architectural styles and surroundings. Beyond color, the texture of the siding plays a key role in its aesthetic appeal. The inherent corrugation provides a natural texture, but some manufacturers offer variations in the depth and profile of the corrugations, leading to subtle differences in the overall visual effect. Additionally, some siding may have a lightly textured surface, enhancing the visual interest and masking minor imperfections. The finish can also range from a smooth, matte look to a slightly more textured, rustic appearance.

Impact of Siding Profiles

The profile of the corrugated fiber cement siding significantly influences its visual impact. Different wave patterns, such as a classic shallow wave, a more pronounced deep wave, or even a more contemporary, flatter profile, create distinct aesthetic effects. The size of the panels also plays a crucial role; larger panels lend a more modern and minimalist look, while smaller panels can create a more traditional or detailed appearance. The spacing between panels, and the choice of exposed fasteners or hidden fastening systems, also contribute to the overall design. For example, closely spaced panels with visible fasteners might evoke a rustic, industrial feel, whereas wider panels with hidden fasteners could create a more sleek and contemporary look.

Aesthetic Comparison to Other Cladding Materials

Compared to other cladding materials, corrugated fiber cement siding offers a unique blend of durability and aesthetic appeal. Its texture and color options allow it to integrate seamlessly into various architectural styles. In contrast to the smooth, uniform appearance of vinyl siding, fiber cement offers a more textured, natural look. Compared to wood siding, it requires significantly less maintenance while retaining a similar visual warmth, especially when used in earth-toned colors. Compared to brick or stone, fiber cement offers a lighter, more modern alternative, particularly suitable for contemporary designs. Its adaptability allows it to complement both traditional and modern architectural styles, often serving as a cost-effective alternative to more expensive materials.

Examples of Corrugated Fiber Cement Siding in Building Designs

The versatility of corrugated fiber cement siding is evident in its diverse applications.

- Residential Homes: It can be used to create a charming farmhouse aesthetic with a muted color palette and subtle wave patterns, or a sleek, contemporary look with larger panels and a bolder color choice. A coastal home might use light blues and grays, while a mountain home might incorporate earthy browns and greens.

- Commercial Buildings: The material’s durability and low-maintenance nature make it ideal for commercial applications. It can be used on industrial buildings to create a rugged, utilitarian aesthetic, or on more modern office spaces to contribute to a clean, minimalist design. A variety of color choices can be employed to match branding or complement surrounding structures.

- Agricultural Structures: Its resilience to harsh weather conditions makes it suitable for barns, sheds, and other agricultural buildings. Neutral colors like grays and browns blend seamlessly into the landscape.

Visual Descriptions of Siding Installation Patterns

The way corrugated fiber cement siding is installed significantly impacts its visual effect.

- Vertical Installation: Creates a sense of height and can make a building appear taller and more slender. This pattern is often used to emphasize the vertical lines of a structure.

- Horizontal Installation: Emphasizes the building’s width and creates a more grounded, stable appearance. This is a common choice for many architectural styles.

- Diagonal Installation: A less common but striking option, diagonal installation adds a dynamic and modern feel, breaking up the monotony of straight lines.

- Mixed Installation Patterns: Combining vertical and horizontal sections can create visual interest and highlight architectural details. This approach can be used to draw attention to specific features of the building.

Environmental Impact and Sustainability: Corrugated Fiber Cement Siding

Source: alamy.com

Corrugated fiber cement siding offers a compelling blend of durability and aesthetics, but its environmental footprint is a crucial factor to consider. Understanding the life cycle impacts, from manufacturing to disposal, allows for informed choices in building materials. This section will explore the environmental aspects of fiber cement siding, comparing it to alternatives and highlighting its sustainability features.

Manufacturing Environmental Impact

The manufacturing process of fiber cement siding involves several stages, each with its own environmental implications. Cement production, a significant component, contributes to greenhouse gas emissions, primarily carbon dioxide, due to the calcination of limestone. The extraction and processing of other raw materials, such as cellulose fibers and silica sand, also have associated environmental impacts, including land use changes and potential water pollution. However, advancements in manufacturing techniques are continuously being implemented to reduce the environmental burden, such as the incorporation of supplementary cementitious materials and optimized energy-efficient kilns. These efforts aim to minimize the carbon footprint and resource consumption throughout the manufacturing process.

Lifecycle Environmental Impact Compared to Alternatives

Fiber cement siding generally demonstrates a favorable lifecycle environmental impact compared to some alternative materials. For example, vinyl siding, while often perceived as environmentally friendly due to its recyclability, relies heavily on petroleum-based products during manufacturing, resulting in a higher carbon footprint. Wood siding, while a natural material, can contribute to deforestation and requires significant maintenance, including potential pesticide use. Metal siding, while durable, has a high embodied energy associated with its production and transportation. A comprehensive life cycle assessment (LCA) considering factors such as manufacturing, transportation, installation, maintenance, and disposal, would be required to make a definitive comparison across all materials; however, many studies suggest that fiber cement siding generally performs competitively, especially when considering its longevity and minimal maintenance needs.

Recyclability and Disposal Options, Corrugated fiber cement siding

While not directly recyclable in the same way as some materials, fiber cement siding can be disposed of responsibly. Many demolition and construction waste recycling facilities accept fiber cement siding, where it can be processed and used as aggregate in other construction projects, reducing landfill burden. Alternatively, responsible disposal at designated landfill sites ensures minimal environmental impact. In some regions, initiatives are underway to explore innovative recycling methods that further reduce the environmental impact of fiber cement siding at end-of-life.

Energy Efficiency Benefits

Fiber cement siding contributes to energy efficiency by providing superior insulation compared to some other siding materials. Its inherent density and composition help to reduce heat transfer, lowering the energy required for heating and cooling a building. This translates to reduced energy consumption, lower utility bills, and a smaller carbon footprint for the building over its lifespan. The improved thermal performance is particularly beneficial in climates with significant temperature variations. The reduction in energy demand can also contribute to lower greenhouse gas emissions associated with electricity generation.

Use of Recycled Materials

Many manufacturers incorporate recycled materials into the production of fiber cement siding. This can include fly ash, a byproduct of coal combustion, and other industrial byproducts. By using these recycled materials, the overall demand for virgin resources is reduced, decreasing the environmental impact associated with resource extraction and processing. The utilization of recycled materials not only contributes to sustainability but also reduces landfill waste, promoting a circular economy model. The percentage of recycled content varies depending on the manufacturer and specific product, but it represents a significant step towards environmentally responsible production.

Cost and Value Considerations

Source: hw.net

Choosing the right siding for your home involves careful consideration of both upfront costs and long-term value. Corrugated fiber cement siding presents a compelling case, balancing initial investment with substantial long-term benefits. Understanding the various cost factors and their impact on your overall investment is crucial for making an informed decision.

Cost Breakdown of Corrugated Fiber Cement Siding

The total cost of installing corrugated fiber cement siding is influenced by several factors. Material costs vary depending on the manufacturer, thickness, color, and texture of the siding. Labor costs are significantly affected by the complexity of the project, the size of the house, and regional labor rates. Additional costs might include permits, demolition of existing siding (if applicable), and the cost of any necessary underlayment or flashing. A typical range for material costs alone can vary from $3 to $8 per square foot, while labor costs can add another $3 to $6 per square foot, leading to a total installed cost of $6 to $14 per square foot, depending on the project specifics. This is a broad estimate, and obtaining multiple quotes from reputable contractors in your area is recommended for accurate pricing.

Comparison of Initial and Long-Term Costs

While the initial cost of fiber cement siding might seem higher than some alternatives like vinyl or wood, its longevity and low maintenance requirements translate to significant long-term savings. Fiber cement is incredibly durable, resistant to rot, insects, and fire, minimizing the need for frequent repairs or replacements. This durability significantly reduces long-term ownership costs compared to materials requiring more frequent maintenance or replacement. For instance, while vinyl siding might have a lower initial cost, it can be susceptible to damage from hail or strong winds, potentially requiring costly repairs over time. Wood siding, while aesthetically pleasing, demands regular painting or staining to prevent deterioration, adding to the overall cost over the siding’s lifespan.

Impact on Property Value

Installing high-quality, durable siding like fiber cement can significantly increase your property’s value. Appraisers often consider the condition and type of siding when assessing a home’s worth. The enhanced curb appeal and improved energy efficiency (due to fiber cement’s insulating properties) contribute to a higher market value. A recent study in a major metropolitan area showed that homes with fiber cement siding sold for an average of 3-5% more than comparable homes with vinyl or aluminum siding, highlighting the positive return on investment. This increase in value is particularly relevant when considering resale.

Factors Influencing Overall Cost

Several factors can influence the overall cost of fiber cement siding. The size and complexity of your home’s exterior will directly impact both material and labor costs. The chosen color and texture can also influence pricing, with some specialized finishes carrying a higher price tag. Regional variations in labor rates and material availability will also play a role. Finally, the contractor’s experience and reputation will affect the overall cost, with more experienced contractors often charging a premium for their expertise. Obtaining multiple bids from reputable contractors is essential for comparing costs and ensuring you receive a fair price.

Cost-Benefit Analysis of Siding Options

| Siding Type | Initial Cost (per sq ft) | Maintenance | Lifespan (Years) |

|---|---|---|---|

| Fiber Cement | $6-$14 | Low | 50+ |

| Vinyl | $2-$5 | Moderate | 20-30 |

| Wood | $4-$10 | High | 15-25 |

| Aluminum | $3-$7 | Low to Moderate | 30-40 |

Final Conclusion

Source: blueridgeexteriors.com

Corrugated fiber cement siding presents a compelling blend of durability, aesthetics, and sustainability. By carefully considering the material properties, installation techniques, design possibilities, and long-term costs, you can confidently assess whether this siding option aligns with your project’s needs and budget. Remember to factor in regional variations in cost and availability when making your final decision. With proper installation and maintenance, this siding promises lasting beauty and protection for your building.

Key Questions Answered

What are the common problems with corrugated fiber cement siding?

Potential issues include cracking (due to improper installation or extreme temperature changes), staining (from mildew or algae), and chipping (from impact). Regular maintenance helps mitigate these risks.

How long does corrugated fiber cement siding last?

With proper care, corrugated fiber cement siding can last 50 years or more, significantly longer than many other siding options.

Is corrugated fiber cement siding difficult to install?

While it requires some skill and the right tools, many homeowners successfully install it themselves. However, for large projects or complex installations, professional help is recommended.

Can I paint corrugated fiber cement siding?

Yes, many brands are paintable, but it’s essential to use paints specifically designed for fiber cement siding to ensure proper adhesion and longevity.

Is fiber cement siding fire resistant?

Yes, fiber cement siding is highly fire-resistant and offers excellent protection against fire spread.