Berridge Siding A Comprehensive Guide

Berridge siding offers a compelling blend of aesthetics, durability, and practicality for homeowners seeking a superior exterior cladding solution. This guide delves into the diverse aspects of Berridge siding, from its manufacturing process and diverse styles to installation techniques, maintenance best practices, and long-term cost-benefit analysis. We’ll explore its environmental impact and compare it to other popular siding options, ultimately equipping you with the knowledge to make an informed decision.

We will cover everything from choosing the right Berridge siding style and color to understanding the installation process and ensuring its longevity. We’ll also address common concerns and provide helpful tips to guide you through each step, from initial planning to long-term maintenance.

Berridge Siding

Berridge siding offers a durable and aesthetically pleasing exterior cladding solution for homes and commercial buildings. This detailed overview explores the product’s features, benefits, and comparisons to other popular siding options.

Berridge Siding Materials

Berridge siding utilizes a variety of high-quality materials depending on the specific product line. Common materials include engineered wood, fiber cement, and vinyl, each offering unique properties in terms of durability, maintenance, and aesthetic appeal. Engineered wood options often incorporate composite materials for enhanced strength and weather resistance. Fiber cement blends cement with cellulose fibers for a strong, fire-resistant product. Vinyl siding is known for its affordability and low maintenance. The specific composition of each Berridge siding product is clearly detailed in its product specifications.

Berridge Siding Styles and Colors

Berridge siding is available in a wide range of styles to complement various architectural designs. Options include traditional clapboard, contemporary vertical panels, and more intricate designs that mimic the look of natural wood or stone. A diverse palette of colors is also offered, ranging from classic earth tones to modern shades, allowing homeowners to customize their exterior to their preferences. Color samples and style guides are typically available from Berridge siding dealers or on their website.

Berridge Siding Manufacturing Process

The manufacturing process for Berridge siding varies slightly depending on the chosen material. Engineered wood siding often involves a layering process, combining different wood components and resins under high pressure. Fiber cement siding involves mixing cement, cellulose fibers, and other additives, followed by molding and curing. Vinyl siding is typically extruded, a process that melts and shapes plastic into long continuous lengths. Strict quality control measures are implemented throughout the manufacturing process to ensure consistent quality and performance.

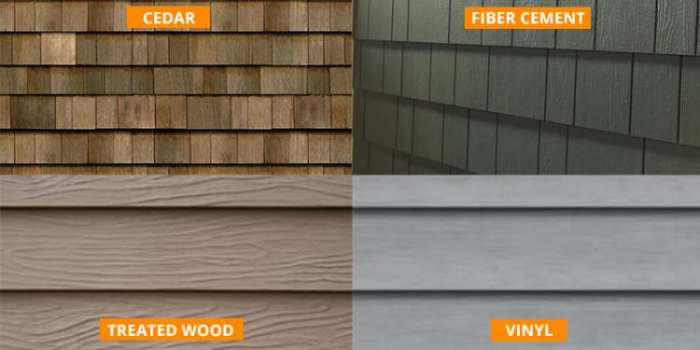

Berridge Siding Compared to Other Siding Options

Berridge siding offers a competitive alternative to other popular siding choices. Compared to vinyl siding, Berridge often provides a more premium aesthetic and potentially greater durability, although it may come at a higher initial cost. Compared to wood siding, Berridge options offer superior resistance to rot, insect infestation, and moisture damage, requiring less maintenance. In comparison to fiber cement siding, Berridge may offer a wider range of styles and colors, although the price point may vary depending on the specific product.

Berridge Siding Price Comparison

The cost of Berridge siding varies depending on the chosen material, style, and color. The following table provides a general price comparison, keeping in mind that actual costs may fluctuate based on location, installer, and project specifics. These prices represent estimated costs per square foot and are intended for illustrative purposes only.

| Siding Type | Price Range ($/sq ft) | Notes |

|---|---|---|

| Berridge Engineered Wood | $4.00 – $7.00 | Higher end, superior durability |

| Berridge Fiber Cement | $3.50 – $6.00 | Strong, fire-resistant |

| Berridge Vinyl | $2.00 – $4.00 | Affordable, low maintenance |

Berridge Siding

Berridge siding offers a durable and aesthetically pleasing exterior cladding option for homes and buildings. Proper installation and consistent maintenance are key to maximizing its lifespan and preserving its attractive appearance. This section details the process of installing Berridge siding, provides maintenance best practices, addresses common installation problems and solutions, and Artikels necessary tools and equipment.

Berridge Siding Installation Steps

Installing Berridge siding involves a series of precise steps to ensure a watertight and visually appealing finish. Preparation is crucial for a successful installation. Failing to adequately prepare the surface can lead to problems later.

- Preparation: Begin by thoroughly cleaning the wall surface, removing any loose debris, old siding, or paint. Repair any damaged areas of the underlying sheathing or wall structure. Ensure the surface is level and plumb. Install appropriate house wrap or weather barrier.

- Framing and Furring Strips: Install furring strips to create a level surface for the siding and to provide proper ventilation. These strips should be evenly spaced and securely fastened.

- Starter Strip Installation: Install the starter strip at the bottom of the wall, ensuring it is level and aligned. This provides a consistent starting point for the siding panels.

- Siding Panel Installation: Begin installing siding panels from the bottom, overlapping each panel according to the manufacturer’s instructions. Use appropriate fasteners, ensuring they are driven straight and flush to avoid damage to the siding.

- J-Channel and Corner Trim: Install J-channel around windows and doors and corner trim at exterior corners to provide a neat and finished look.

- Finishing Touches: Install any necessary trim pieces, such as soffit and fascia, to complete the installation. Caulk around windows, doors, and other penetrations to prevent water infiltration.

Berridge Siding Maintenance

Regular maintenance significantly extends the life of Berridge siding. Neglecting maintenance can lead to premature deterioration and costly repairs.

- Annual Inspection: Inspect the siding annually for any signs of damage, such as cracks, loose panels, or water damage. Address any issues promptly.

- Cleaning: Clean the siding regularly using a soft brush, mild detergent, and water. Avoid using high-pressure washers, as they can damage the siding.

- Caulk Repair: Regularly inspect and repair any damaged caulking around windows, doors, and other penetrations to prevent water intrusion.

- Paint or Stain (If Applicable): If your Berridge siding is painted or stained, repaint or restain it as needed to maintain its appearance and protect it from the elements.

Common Berridge Siding Installation Problems and Solutions

Several common problems can arise during Berridge siding installation. Knowing how to address these issues proactively ensures a successful project.

| Problem | Solution |

|---|---|

| Uneven siding installation | Ensure proper framing and use a level to check alignment throughout the installation process. |

| Water damage | Properly install flashing and caulking around windows, doors, and other penetrations. Address any leaks promptly. |

| Fastener damage | Use appropriate fasteners and drive them straight and flush to avoid damaging the siding. |

| Improper panel overlap | Follow the manufacturer’s instructions for proper panel overlap to ensure a watertight installation. |

Tools and Equipment for Berridge Siding Installation

The proper tools are essential for a successful and efficient Berridge siding installation. Having the right equipment on hand saves time and prevents frustration.

- Measuring tape

- Level

- Circular saw

- Drill with appropriate drill bits

- Hammer

- Safety glasses

- Work gloves

- Caulk gun

- Utility knife

- Nail gun (optional, but recommended for efficiency)

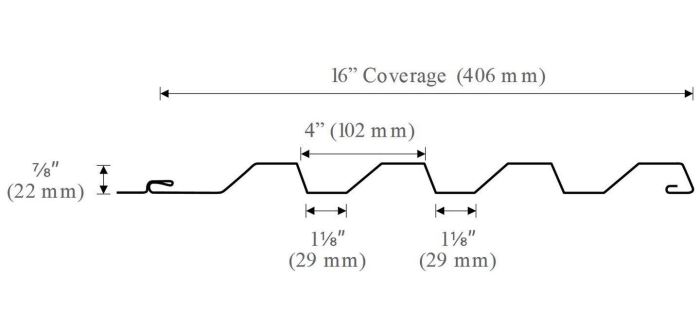

Visual Guide: Installing a Section of Berridge Siding

Berridge Siding

Source: legacyusa.com

Berridge siding is a popular choice for homeowners seeking a durable and aesthetically pleasing exterior cladding option. Understanding the warranty and reading customer reviews are crucial steps in making an informed decision before investing in this product. This section will provide a comprehensive overview of both aspects.

Berridge Siding Warranty Information

The specific warranty offered by Berridge siding manufacturers varies depending on the product line and the year of purchase. It’s essential to consult the original documentation provided with your siding purchase for the most accurate and up-to-date information. Generally, warranties cover manufacturing defects and material failures for a specific period, often ranging from several years to decades. Some warranties may cover labor costs associated with repairs, while others may only cover the replacement of defective materials. Warranties may also include limitations or exclusions, such as those related to improper installation or damage caused by extreme weather events. Always carefully review the warranty terms and conditions before installation.

Berridge Siding Customer Reviews and Feedback

Customer reviews offer valuable insights into the real-world performance and longevity of Berridge siding. An analysis of online reviews and feedback from various sources reveals a mixed bag of experiences.

To provide a clearer picture, customer reviews can be categorized as follows:

- Positive Reviews: Many customers praise Berridge siding for its attractive appearance, durability, and resistance to weather damage. Positive feedback often highlights the ease of maintenance and the long-lasting color retention of the siding.

- Negative Reviews: Negative feedback frequently centers on issues with installation, such as improper fitting or damage during the process. Some customers report problems with fading or discoloration over time, despite the manufacturer’s claims of colorfastness. Other complaints involve difficulties in obtaining warranty service or dealing with customer support.

- Neutral Reviews: Neutral reviews often reflect a satisfactory experience without any outstanding positive or negative aspects. These reviews typically describe Berridge siding as a functional and adequate product that meets basic expectations.

Common Complaints Regarding Berridge Siding

Several common issues consistently appear in customer reviews. These include:

- Installation Problems: Improper installation can lead to gaps, leaks, and premature deterioration of the siding.

- Color Fading: Some customers report noticeable fading or discoloration of the siding over time, especially in areas with significant sun exposure.

- Warranty Claims: Difficulties in processing warranty claims and obtaining satisfactory resolution are frequently cited.

- Customer Service Issues: Negative experiences with customer service representatives are a recurring theme in negative reviews.

Comparison of Berridge Siding Warranty to Competitors

Direct comparison of Berridge siding’s warranty to competitors requires specifying the exact Berridge product and the competitor’s products. Warranty lengths and coverage can vary significantly between manufacturers and product lines. Some competitors offer longer warranties, while others may provide more comprehensive coverage for labor or specific types of damage. Thorough research comparing warranties from various manufacturers is necessary to determine the best value for your investment.

Berridge Siding

Source: visexterior.com

Berridge siding, like any building material, has an environmental footprint encompassing its production, use, and disposal. Understanding this footprint is crucial for responsible construction and building choices. This section details the environmental impact of Berridge siding, comparing it to alternatives and highlighting sustainability efforts.

Manufacturing Environmental Impact, Berridge siding

The manufacturing process of Berridge siding, like most building materials, consumes energy and resources. This includes the extraction and processing of raw materials (likely wood fiber or a composite material depending on the specific Berridge product), the energy used in manufacturing processes, and the generation of waste. The specific environmental impact varies based on the exact composition of the siding and the manufacturing techniques employed. For example, the use of recycled materials in the manufacturing process can significantly reduce the overall environmental burden. Transportation of the finished product also contributes to the carbon footprint.

Recyclability and Disposal Methods

The recyclability of Berridge siding depends heavily on its composition. Some Berridge siding products may be recyclable, while others may require disposal in landfills. Manufacturers should provide clear information on the appropriate disposal methods for their specific products. Responsible disposal is crucial to minimize the environmental impact of discarded siding. Recycling options may vary by location, so checking with local recycling facilities is recommended. In some cases, repurposing the siding for other uses may be possible, extending its lifespan and reducing waste.

Environmental Footprint Comparison

Comparing the environmental footprint of Berridge siding to alternatives such as vinyl, aluminum, or fiber cement siding requires a comprehensive life-cycle assessment (LCA). An LCA considers the environmental impacts of each material throughout its entire life cycle, from raw material extraction to manufacturing, transportation, use, and disposal. While some materials may have lower embodied carbon during manufacturing, others may have longer lifespans or better recyclability. Factors such as durability, maintenance needs, and energy efficiency during the building’s lifespan should also be considered. For example, wood siding, while often renewable, may require more frequent maintenance and replacement than other options, impacting its overall environmental performance. A detailed LCA is needed for a precise comparison.

Berridge Siding Sustainability Initiatives

Many siding manufacturers, including those producing Berridge siding, are actively pursuing sustainability initiatives. These may include using recycled materials in their products, optimizing manufacturing processes to reduce energy consumption and waste, and investing in renewable energy sources for their facilities. Some manufacturers also offer products with certifications demonstrating their commitment to sustainable practices, such as certifications related to responsible forestry or low-VOC emissions. Consumers can look for these certifications when choosing siding to support environmentally responsible manufacturing practices.

Environmental Impact Factors of Berridge Siding

| Factor | Impact | Mitigation Strategies | Comparison to Alternatives |

|---|---|---|---|

| Raw Material Extraction | Energy consumption, habitat disruption (depending on materials) | Sustainable sourcing, recycled materials | Varies widely depending on the alternative material (e.g., wood vs. vinyl) |

| Manufacturing Process | Energy consumption, emissions, waste generation | Efficient manufacturing techniques, renewable energy | Depends on the manufacturing processes used for different materials |

| Transportation | Fuel consumption, emissions | Optimized logistics, local sourcing | Distance to manufacturing facility and transportation mode affect all materials |

| Disposal/Recycling | Landfill space, potential environmental pollutants | Recycling programs, repurposing | Recyclability varies greatly among siding materials |

Berridge Siding

Source: construction.com

Berridge siding offers a compelling combination of durability, aesthetics, and long-term value. Understanding the cost-benefit analysis is crucial for homeowners considering this investment. This section will break down the initial costs, compare them to alternatives, and project the potential return on investment.

Long-Term Cost Savings with Berridge Siding

Berridge siding’s superior durability translates to significant long-term cost savings. Unlike other siding materials that may require frequent repairs, repainting, or even complete replacement within a shorter timeframe, Berridge siding is engineered for exceptional longevity. Its resistance to weather damage, insect infestation, and fading minimizes the need for costly maintenance and replacements over the years. For example, a homeowner might avoid the $5,000-$10,000 expense of replacing damaged vinyl siding every 15-20 years by opting for Berridge siding, which could last significantly longer, potentially exceeding 50 years with proper maintenance. This translates to substantial savings over the lifetime of the home.

Comparison of Berridge Siding Costs to Other Options

The initial investment in Berridge siding may be higher than some less durable alternatives like vinyl or aluminum siding. However, this higher upfront cost is often offset by the reduced maintenance and extended lifespan. A rough comparison might show vinyl siding costing $5-$10 per square foot installed, while fiber cement (a comparable material in terms of durability) can range from $10-$15 per square foot, and Berridge siding falling within a similar range to fiber cement, depending on the specific style and features chosen. The key is to consider the total cost of ownership over the life of the siding, not just the initial purchase price.

Return on Investment (ROI) for Berridge Siding

The ROI for Berridge siding is positive due to its longevity and reduced maintenance needs. While precise ROI calculations depend on various factors (discussed below), a longer lifespan translates directly to savings on future repairs and replacements. For instance, avoiding a $7,000 repainting job every 10 years, a common expense with other siding types, adds significant value. Moreover, the enhanced curb appeal associated with Berridge siding can increase the home’s resale value, further boosting the ROI. A properly installed and maintained Berridge siding system can easily add 10-15% to the value of your home.

Factors Influencing the Overall Cost of Berridge Siding Installation

Several factors influence the total cost of Berridge siding installation. These include:

- The size of the house: Larger houses naturally require more materials and labor.

- The complexity of the house design: Houses with intricate architectural details or multiple levels will necessitate more time and effort.

- The chosen style and color of Berridge siding: Some styles and colors may be more expensive than others.

- Labor costs: Labor rates vary by geographic location and contractor experience.

- Permits and inspections: These costs can vary depending on local regulations.

- Additional features: Features like trim, flashing, and underlayment will increase the overall cost.

Cost Breakdown for Berridge Siding Installation

It’s essential to obtain detailed quotes from multiple reputable contractors. A typical cost breakdown might look like this:

- Materials (Siding, Trim, Fasteners, Underlayment): This portion varies greatly based on the size of the house and material choices but can range from $5,000 to $20,000 or more.

- Labor: Labor costs typically range from $3,000 to $10,000 or more, depending on the size and complexity of the project and regional labor rates.

- Permits and Inspections: These costs are typically a few hundred dollars.

- Waste Removal: Expect to pay a few hundred dollars for proper disposal of old siding and construction debris.

Note: These are estimates, and actual costs will vary based on the factors mentioned above. Always obtain multiple detailed quotes from qualified contractors.

Outcome Summary

Ultimately, the choice of Berridge siding hinges on your individual needs and preferences, balanced against factors like budget, aesthetic goals, and long-term maintenance considerations. This guide has provided a thorough exploration of Berridge siding, empowering you to weigh the pros and cons and decide if it’s the right fit for your home. Remember to consult with professionals for installation and to review the manufacturer’s warranty for comprehensive coverage.

FAQ Summary

What is the average lifespan of Berridge siding?

With proper installation and maintenance, Berridge siding can last for several decades, often outperforming other siding materials.

Is Berridge siding resistant to pests and insects?

The specific pest resistance depends on the material composition. Check the manufacturer’s specifications for details on pest resistance.

Can I install Berridge siding myself, or do I need a professional?

While DIY installation is possible for some, professional installation is generally recommended for optimal results and warranty coverage.

Does Berridge siding require regular painting or staining?

This depends on the type of Berridge siding chosen. Some varieties are designed to resist fading and weathering without requiring regular repainting.

How does Berridge siding compare to other eco-friendly siding options?

Compare Berridge siding’s recyclability and manufacturing processes to alternatives like recycled plastic lumber or sustainably harvested wood to determine its environmental impact.