Cost of Hardie Plank Siding Installed

Cost of Hardie Plank Siding Installed: Thinking about upgrading your home’s exterior with the durable and attractive Hardie Plank siding? Understanding the costs involved is crucial for successful planning. This guide breaks down the factors influencing the price of Hardie Plank siding installation, from material costs and labor rates to regional variations and project complexity. We’ll explore different scenarios to give you a realistic picture of what to expect, helping you budget effectively for your home improvement project.

We’ll delve into the specifics of material costs, including the price per square foot of various Hardie Plank profiles and colors, as well as the additional expenses for fasteners, flashing, and trim. Labor costs will be examined, comparing professional installation to DIY approaches and highlighting potential hidden costs. Regional differences in both material and labor prices will be addressed, providing a comprehensive overview of the cost variations across the country. Finally, we’ll offer cost-saving strategies to help you manage your budget while achieving your desired aesthetic.

Factors Influencing Hardie Plank Siding Installation Costs

Source: thesidingking.com

The cost of installing Hardie Plank siding is influenced by a variety of factors, making it crucial to understand these elements for accurate budgeting and realistic expectations. This detailed breakdown will explore the key components contributing to the overall expense, enabling you to make informed decisions throughout the process.

Material Costs

Hardie Plank siding itself constitutes a significant portion of the total cost. The price per square foot varies based on the chosen profile (e.g., lap siding, shiplap, vertical), color, and the quantity needed. Premium colors and unique profiles often command higher prices. Additionally, the need for extra materials due to waste or unforeseen circumstances can inflate the budget. For example, a complex design requiring many cuts might result in higher material costs than a simpler installation. Purchasing materials in bulk can often lead to slight discounts.

Labor Rates

Labor costs represent a substantial part of the overall expense. The hourly or daily rate charged by contractors varies significantly depending on factors such as location, experience, and demand. Experienced installers with a proven track record typically charge more than newer companies. The complexity of the project, including the need for specialized techniques (e.g., working around intricate window details or difficult angles), also impacts labor time and thus the final cost. A simple, straightforward installation on a rectangular house will likely cost less in labor than a project involving numerous dormers, bay windows, or other complex architectural features.

Regional Variations

Geographic location significantly impacts both material and labor costs. Areas with high demand for construction services or limited availability of skilled labor tend to have higher labor rates. Transportation costs for materials can also increase prices in remote locations. For instance, a project in a rural area might incur higher costs due to increased transportation fees for the siding and associated materials compared to a similar project in a major metropolitan area. Furthermore, local building codes and regulations might necessitate additional labor or materials, adding to the overall expense.

Project Size and Complexity

The size of the house and the complexity of the design heavily influence the overall cost. A larger house naturally requires more materials and labor, resulting in a higher price tag. Complex designs with many angles, intricate trim work, or specialized features like multiple dormers or bay windows increase both labor time and material needs, driving up the cost. For example, a two-story house with many angles and intricate trim details will likely be more expensive than a single-story ranch-style house with a simple design.

Hardie Plank Siding Profiles and Colors

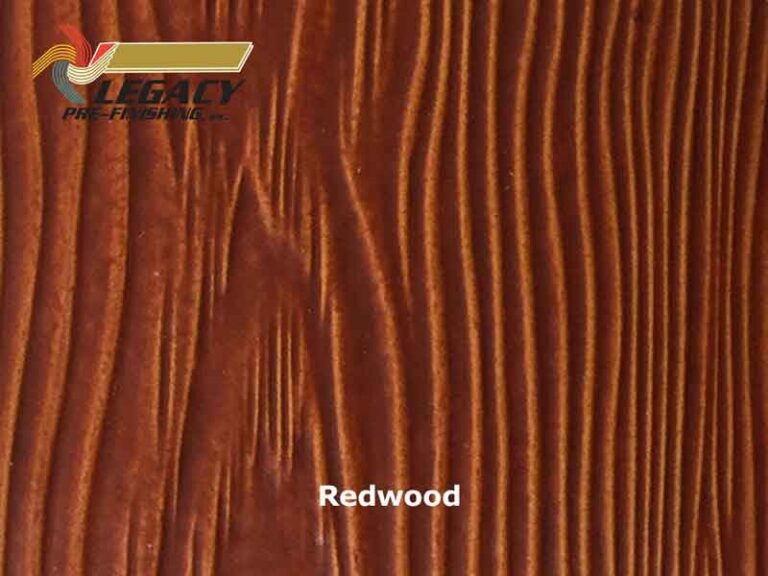

Different Hardie Plank profiles and colors have varying price points. Some profiles, like those with intricate detailing or larger planks, might be more expensive than simpler, standard profiles. Similarly, premium colors, especially those requiring special coatings or finishes, might cost more than standard colors. For example, a custom-mixed color or a highly textured finish might significantly increase the material cost compared to a standard, readily available color.

| Factor | Description | Cost Impact | Example |

|---|---|---|---|

| Material Costs | Cost of Hardie Plank siding, trim, and fasteners. | High | Premium color siding costing $4/sq ft vs. standard color at $3/sq ft. |

| Labor Rates | Hourly or daily rate of installation crew. | High | Experienced installer charging $75/hour vs. less experienced installer at $50/hour. |

| Regional Variations | Differences in material and labor costs based on location. | Medium | Higher labor costs in a city with high demand vs. a rural area with lower demand. |

| Project Size & Complexity | Size of the house and intricacy of the design. | High | Complex design with many angles costing significantly more than a simple design. |

| Siding Profile & Color | Cost varies based on chosen profile and color. | Medium | A textured, premium color costing more than a standard smooth finish. |

Material Costs of Hardie Plank Siding

Understanding the material costs is crucial for budgeting your Hardie Plank siding project. The total cost will depend on several factors, including the amount of siding needed, the chosen profile and color, and the cost of supplementary materials. This section breaks down these costs to give you a clearer picture.

The price of Hardie Plank siding itself varies considerably. Several factors influence the final cost per square foot.

Hardie Plank Siding Price Per Square Foot

The cost of Hardie Plank siding typically ranges from $2 to $8 per square foot, before installation. This wide range reflects differences in profile complexity and color choices. Simpler profiles, such as the standard lap siding, generally fall on the lower end of this spectrum. More intricate profiles, like those with a shiplap or beaded design, command a higher price. Similarly, popular colors may be slightly more expensive than less common ones due to higher demand and potentially different manufacturing processes. For example, a basic lap siding in a neutral color might cost around $2-$4 per square foot, while a more complex profile in a premium color could easily reach $6-$8 or more.

Costs of Additional Materials

Beyond the siding itself, you’ll need various additional materials for a successful installation. These include fasteners, flashing, and trim pieces, all of which contribute to the overall project expense. Careful planning and accurate measurements are vital to minimize waste and unnecessary expenses.

- Fasteners: Galvanized nails or screws specifically designed for Hardie Plank are essential. Expect to pay around $10-$20 per box, with each box containing several hundred fasteners. The exact quantity needed will depend on the size of your project.

- Flashing: Flashing, used to prevent water penetration around windows, doors, and other penetrations, typically costs between $2 and $5 per linear foot, depending on the material (aluminum or galvanized steel).

- Trim: J-channel, corner boards, and other trim pieces add to the overall aesthetic appeal and protect the edges of the siding. These can range from $2 to $10 per linear foot depending on the material and profile.

- Caulk and Sealant: High-quality caulk and sealant are crucial for weatherproofing. A tube of quality exterior caulk might cost between $5 and $15.

- Primer and Paint (if needed): If you opt for a primed siding and decide to paint it a custom color, factor in the cost of high-quality exterior paint and primer. Prices vary greatly depending on the brand and quantity needed.

Bulk Purchasing Savings

Purchasing materials in bulk can often lead to significant cost savings. Most building supply stores offer discounts for larger orders. While this requires careful planning and accurate measurements to avoid overbuying, the potential savings can be substantial, especially on items like siding and fasteners. For example, buying a full pallet of siding might offer a 10-15% discount compared to purchasing individual pieces. Similarly, buying fasteners in bulk can save several dollars per box.

Labor Costs for Hardie Plank Siding Installation

Labor costs represent a significant portion of the overall expense for Hardie Plank siding installation. Understanding these costs, which vary based on several factors, is crucial for accurate budgeting. This section will break down the different labor components and provide a realistic range of costs to expect.

Labor Cost Ranges per Square Foot, Cost of hardie plank siding installed

Labor costs for Hardie Plank siding installation typically range from $2 to $8 per square foot. This wide range reflects differences in project complexity, geographic location, contractor experience, and the overall condition of the existing siding. For instance, a simple installation on a new, straightforward home will fall toward the lower end of the spectrum, while a complex project involving extensive repairs or intricate detailing will command a higher price. A project requiring significant removal of existing siding or substantial carpentry work before installation will also increase the labor cost. Factors like difficult terrain or accessibility issues can also drive up the cost.

Types of Labor Involved and Respective Costs

Several distinct labor phases contribute to the overall installation cost. Preparation work, which may include removing existing siding, repairing damaged sheathing, and installing necessary flashing and water barriers, typically accounts for a significant portion of the labor. This preparatory phase can range from $1 to $3 per square foot. The actual installation of the Hardie Plank siding itself usually costs between $1 and $5 per square foot, depending on the complexity of the design. Finally, cleanup, which includes removing debris and restoring the work area to a presentable condition, usually adds a small but essential cost, often incorporated into the overall installation price.

Professional Contractor vs. DIY Installation: Labor Cost Comparison

Hiring a professional contractor offers several advantages, including expertise, efficiency, warranty protection, and proper waste disposal. While the upfront cost might seem higher, a professional’s efficiency can often mitigate this difference over time. However, DIY installation can significantly reduce labor costs, potentially saving you $2 to $8 per square foot. However, this approach requires considerable time, skill, and the acquisition of necessary tools. A miscalculation or error in a DIY installation can lead to costly repairs or even structural damage down the line, potentially negating any initial savings. Therefore, the financial wisdom of a DIY approach hinges heavily on your skill level and the complexity of the project.

Potential Hidden Labor Costs

Beyond the direct labor costs, several hidden expenses can significantly impact the final price. Permits, required by most municipalities for exterior renovations, can add hundreds or even thousands of dollars depending on location and project scope. Waste disposal fees, particularly crucial for removing old siding and other construction debris, can also add up. These fees vary depending on the volume of waste and local regulations. Finally, unforeseen complications during the installation process, such as encountering rotted wood or unexpected structural issues, can lead to additional labor costs. These unexpected expenses highlight the importance of obtaining detailed estimates from reputable contractors before commencing the project.

Regional Variations in Installation Costs

Geographical location significantly impacts the overall cost of Hardie Plank siding installation. This variation stems from differences in both material and labor costs across different regions of the country. Several factors contribute to these regional disparities, influencing the final price homeowners pay for their new siding.

Factors Contributing to Regional Cost Differences

Several key factors contribute to the regional variations in Hardie Plank siding installation costs. These include the cost of transportation and shipping for materials, local labor market conditions (including the demand for skilled labor and prevailing wage rates), building codes and regulations that may influence installation methods, and the overall cost of living in a particular area. For instance, areas with high costs of living often have higher labor costs, directly impacting the overall project expense. Similarly, regions with limited access to major transportation hubs may experience higher material costs due to increased shipping expenses.

Regional Cost Comparison

The following table provides a general comparison of average Hardie Plank siding installation costs across different regions of the United States. It’s important to note that these are estimates and actual costs can vary based on project specifics, such as the size and complexity of the home, existing siding conditions, and the contractor chosen. These figures are based on data collected from various sources including contractor quotes, industry reports, and cost-of-living indices, averaged across multiple projects within each region.

| Region | Average Material Cost (per sq ft) | Average Labor Cost (per sq ft) | Total Average Cost (per sq ft) |

|---|---|---|---|

| Northeast (e.g., New England) | $3.50 – $4.50 | $5.00 – $7.00 | $8.50 – $11.50 |

| Southeast (e.g., Florida, Georgia) | $3.00 – $4.00 | $4.00 – $6.00 | $7.00 – $10.00 |

| Midwest (e.g., Illinois, Ohio) | $3.25 – $4.25 | $4.50 – $6.50 | $7.75 – $10.75 |

| Southwest (e.g., Texas, Arizona) | $3.00 – $4.00 | $4.00 – $5.50 | $7.00 – $9.50 |

| West Coast (e.g., California, Oregon) | $4.00 – $5.00 | $6.00 – $8.00 | $10.00 – $13.00 |

Illustrative Examples of Hardie Plank Siding Installation Projects: Cost Of Hardie Plank Siding Installed

Source: advanceroofingllc.com

Understanding the cost of Hardie Plank siding installation requires considering project specifics. The following examples illustrate how project size, complexity, and material choices impact the final price. These are estimates, and actual costs may vary based on location and specific contractor pricing.

Project 1: Small Ranch Home

This project involves installing Hardie Plank siding on a 1,500 square foot ranch-style home with a simple design. The homeowner opts for a classic look.

Material Costs: We estimate 1,800 square feet of Hardie Plank siding in the “Classic” profile, allowing for waste and cuts. At an average cost of $3.50 per square foot, the material cost totals $6,300. The chosen color is “Arctic White.” Additional materials, including trim boards, fasteners, and underlayment, add approximately $1,500 to the total.

Labor Costs: The installation, including preparation and cleanup, is estimated at 150 labor hours. At an average labor rate of $50 per hour, the labor cost is $7,500.

Total Cost: The total estimated cost for this project is $6,300 (materials) + $1,500 (additional materials) + $7,500 (labor) = $15,300.

Project 2: Two-Story Colonial Home with Complex Details

This project involves a larger, more complex 2,800 square foot two-story colonial home. The home features intricate trim work, dormers, and multiple gables. The homeowner selects a more detailed siding profile.

Material Costs: The project requires approximately 3,500 square feet of Hardie Plank siding in the “Beaded” profile, accounting for waste and complex cuts. At $4.00 per square foot, the material cost is $14,000. The color chosen is “Cobblestone.” The increased complexity necessitates more trim and underlayment, adding an estimated $3,000.

Labor Costs: The increased complexity and larger surface area require an estimated 300 labor hours. At $50 per hour, the labor cost is $15,000.

Total Cost: The total estimated cost for this project is $14,000 (materials) + $3,000 (additional materials) + $15,000 (labor) = $32,000.

Project 3: Modern Farmhouse with Accent Features

This project features a 2,200 square foot modern farmhouse with a mix of Hardie Plank siding profiles and colors for a visually interesting design.

Material Costs: This project uses 2,500 square feet of “Lap” profile Hardie Plank siding in “Gray” for the main walls. It also incorporates 500 square feet of “Panel” profile in “Black” for accent features. At an average cost of $3.75 per square foot for the Lap siding and $4.25 per square foot for the Panel siding, the material cost is ($3.75 * 2500) + ($4.25 * 500) = $11,875. Additional materials are estimated at $2,000.

Labor Costs: The varied profiles and colors require careful planning and installation, necessitating approximately 225 labor hours. At $50 per hour, the labor cost is $11,250.

Total Cost: The total estimated cost for this project is $11,875 (materials) + $2,000 (additional materials) + $11,250 (labor) = $25,125.

Cost-Saving Strategies for Hardie Plank Siding Installation

Source: lowes.com

Installing Hardie Plank siding can significantly enhance your home’s curb appeal and longevity, but the costs can be substantial. However, with careful planning and strategic choices, you can effectively minimize expenses without sacrificing quality. This section explores several effective cost-saving strategies to help you manage your budget.

Choosing the right approach can lead to significant savings, allowing you to maximize your investment while achieving the desired aesthetic improvements. Remember, prioritizing efficient planning and execution can yield considerable financial benefits.

DIY Preparation Work

Undertaking some preparatory work yourself can significantly reduce overall installation costs. This includes tasks like removing old siding, cleaning the surface, and preparing the area for installation. While you may lack the professional expertise for complex tasks, simpler preparatory work can save money on labor costs. For example, removing old, damaged siding and ensuring a clean surface for the new installation reduces the time professional installers spend on these preliminary steps. This self-sufficiency can translate into savings ranging from 5% to 15% of the total labor costs, depending on the scope of the project and your DIY capabilities.

Siding Profile and Color Selection

The specific profile and color of Hardie Plank siding you choose can impact the final cost. Simpler profiles, like standard lap siding, generally cost less than more intricate designs. Similarly, some colors may be more readily available or require less specialized handling, leading to lower material costs. For instance, choosing a standard color might be 5-10% cheaper than a custom-mixed color requiring special ordering and potentially longer lead times. Avoid overly complex profiles or highly specialized colors unless the added aesthetic value justifies the extra expense.

Cost-Saving Tips

Careful consideration of several factors can significantly reduce the overall cost of your Hardie Plank siding installation. The following points highlight key areas where strategic decisions can lead to substantial savings:

- Negotiate with Contractors: Obtain multiple quotes from different contractors and compare pricing before making a decision. Don’t hesitate to negotiate for a better price.

- Choose Off-Season Installation: Contractors often offer discounts during the off-season (typically fall and winter), as demand is lower.

- Consider Purchasing Materials Directly: Buying materials directly from a supplier, rather than through the contractor, can potentially lower material costs. However, be aware of potential implications for warranties.

- Prioritize Efficient Waste Management: Precise planning and careful measurement during the installation process minimizes material waste, reducing overall costs.

- Bundle Services: If you need additional exterior work, such as window or door replacement, bundling services with the siding installation might result in discounts.

- Explore Financing Options: Consider financing options offered by contractors or lenders to spread out the cost of the project over time.

Summary

Source: homeguide.com

Ultimately, the cost of installing Hardie Plank siding is a multifaceted equation. While the initial investment may seem significant, the long-term benefits of durability, low maintenance, and curb appeal often outweigh the expense. By carefully considering the factors Artikeld in this guide—material choices, labor costs, regional variations, and project specifics—you can make informed decisions and plan a budget that aligns with your goals. Remember, thorough planning and research can lead to a successful and cost-effective Hardie Plank siding installation, enhancing your home’s beauty and value for years to come.

Top FAQs

What is the lifespan of Hardie Plank siding?

Hardie Plank siding is known for its longevity, typically lasting 30-50 years or more with proper maintenance.

Does Hardie Plank siding require regular maintenance?

Minimal maintenance is needed. Occasional cleaning with water and a soft brush is usually sufficient.

Can I install Hardie Plank siding myself?

While possible, professional installation is generally recommended for optimal results and warranty coverage. DIY installation can be challenging and may void warranties.

What are the warranty options for Hardie Plank siding?

James Hardie, the manufacturer, offers warranties that vary depending on the product and installation. Check their website for details.

How do I find a reputable contractor for Hardie Plank siding installation?

Seek referrals, check online reviews, and verify licensing and insurance before hiring a contractor. Get multiple quotes for comparison.