Most Durable Siding for House A Comprehensive Guide

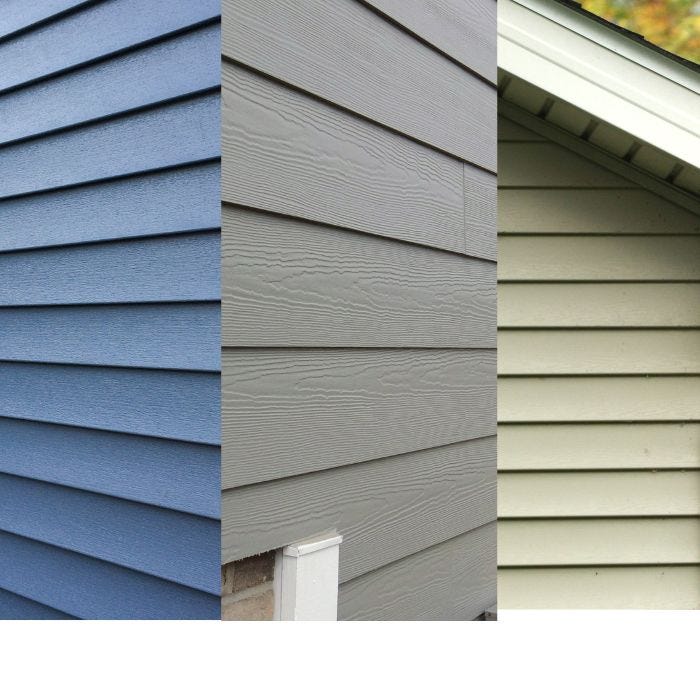

Most durable siding for house? Choosing the right siding is a crucial decision impacting your home’s curb appeal, longevity, and overall value. This guide delves into the world of durable siding materials, exploring various options, their properties, installation best practices, maintenance needs, and long-term cost implications. We’ll help you navigate the complexities of choosing the most suitable and long-lasting siding for your home, considering factors like climate, budget, and personal preferences.

From understanding the manufacturing processes of different siding types like fiber cement, vinyl, and wood, to evaluating their resistance to UV rays and extreme weather conditions, we’ll cover all the essential aspects. We’ll also discuss the importance of proper installation and maintenance to maximize the lifespan of your siding and protect your investment. Ultimately, this guide aims to empower you to make an informed decision, ensuring your home is protected and beautiful for years to come.

Types of Durable House Siding

Choosing the right siding for your home is a crucial decision impacting both aesthetics and longevity. The material you select will significantly influence your home’s curb appeal, energy efficiency, and the overall cost of ownership over its lifespan. Understanding the various types of durable siding available and their characteristics is essential for making an informed choice.

Durable Siding Materials and Their Manufacturing Processes, Most durable siding for house

Selecting durable siding involves considering several factors beyond initial cost. The manufacturing process of each material influences its properties, including strength, resistance to weather damage, and maintenance needs. Below is a table outlining five common durable siding types, along with their manufacturing processes, advantages, and disadvantages.

| Siding Type | Material | Pros | Cons |

|---|---|---|---|

| Fiber Cement | A composite material made from cement, cellulose fibers, and sand. | Durable, fire-resistant, low maintenance, resists pests and rot, paintable. | Can be brittle and prone to cracking if improperly installed, more expensive than vinyl. |

| Vinyl | Polyvinyl chloride (PVC) plastic. | Affordable, low maintenance, water-resistant, variety of colors and styles. | Can fade in sunlight, susceptible to damage from impact, less durable than fiber cement or wood. |

| Wood | Naturally occurring lumber, often treated for rot and pest resistance. | Classic look, aesthetically pleasing, can be repaired easily, relatively easy to install. | Requires regular maintenance (painting, staining), susceptible to rot, insect damage, and fire. |

| Metal | Aluminum, steel, or zinc alloys. | Extremely durable, fire-resistant, low maintenance, long lifespan. | Can dent, susceptible to rust (unless properly coated), can be noisy in rain or hail. |

| Engineered Wood | Composite material combining wood fibers with resins and waxes. | Durable, moisture-resistant, less prone to warping and cracking than solid wood. | Can be more expensive than vinyl, may require more specialized installation. |

Fiber Cement Manufacturing: A slurry of cement, cellulose fibers, and sand is mixed, formed into panels under high pressure, and then cured in a kiln at high temperatures. This process creates a dense, durable material.

Vinyl Manufacturing: PVC resin is combined with stabilizers, pigments, and other additives. The mixture is then extruded into the desired shape and cooled.

Wood Siding Manufacturing: Involves milling lumber from trees, often followed by pressure treatment with preservatives to enhance durability and pest resistance.

Metal Siding Manufacturing: Metal sheets are rolled and formed into various profiles, often with protective coatings (powder coating, zinc galvanization) added for weather resistance and rust prevention.

Engineered Wood Manufacturing: Wood fibers are combined with resins and waxes, then formed into panels using heat and pressure. This process creates a denser, more stable material than solid wood.

Lifespan and Maintenance of Durable Siding

The lifespan and maintenance requirements of siding vary considerably depending on the material and the climate. Understanding these differences is vital for long-term cost planning.

Fiber Cement: With proper installation and minimal maintenance, fiber cement siding can last 50 years or more. Occasional cleaning and repainting every 10-15 years are typically sufficient.

Vinyl: Vinyl siding generally lasts 20-30 years, although its lifespan can be shorter in harsh climates. Regular cleaning with soap and water is usually all that’s required.

Wood: The lifespan of wood siding depends heavily on the type of wood, the quality of the treatment, and the climate. With regular maintenance (painting or staining every 3-5 years), it can last 20-30 years or longer. Untreated wood will degrade much faster.

Metal: Metal siding is exceptionally durable and can last 50 years or more with minimal maintenance. Occasional cleaning may be necessary, and repainting or recoating might be needed after several decades, depending on the finish.

Engineered Wood: Engineered wood siding typically lasts 30-50 years with proper installation and maintenance, often requiring less frequent repainting than solid wood. Regular cleaning and occasional spot repairs might be needed.

Material Properties and Durability

Choosing the right siding for your home involves understanding how material composition directly impacts its lifespan and resistance to the elements. Different materials offer varying degrees of durability, influencing maintenance needs and overall cost-effectiveness over time. This section delves into the specific properties that contribute to a siding’s longevity.

The inherent properties of the material itself are paramount to its durability. Fiber cement, vinyl, and wood, for example, each possess distinct characteristics affecting their resistance to damage and decay. Fiber cement, a composite of cement, sand, and cellulose fibers, boasts exceptional strength and fire resistance. Vinyl siding, a plastic-based material, is known for its low maintenance and resistance to rot and insect infestation. Wood siding, a natural material, offers aesthetic appeal but requires more upkeep to protect against moisture damage, insect infestation, and decay. The composition of each material dictates its inherent strength, flexibility, and susceptibility to environmental factors.

UV Resistance and Weatherproofing in Siding Longevity

UV resistance and effective weatherproofing are critical factors determining siding longevity. Prolonged exposure to ultraviolet (UV) radiation from sunlight can degrade many materials, leading to fading, cracking, and weakening. Weatherproofing, encompassing resistance to moisture, wind, and extreme temperatures, prevents water damage, which is a major contributor to siding failure. Superior UV protection often involves the use of specialized pigments and additives in the manufacturing process. For instance, some high-end vinyl sidings incorporate titanium dioxide, a highly effective UV stabilizer, into their formulation, significantly extending their lifespan and preventing color fading. Proper installation, ensuring a tight seal against moisture penetration, is also crucial for effective weatherproofing. A well-designed overlapping system in siding installation, like that found in some clapboard styles, further enhances water runoff and reduces moisture accumulation.

Effects of Climate Conditions on Siding Materials

Different climates pose unique challenges to various siding materials. Extreme heat can cause expansion and contraction in some materials, potentially leading to warping or cracking. Conversely, extreme cold can embrittle certain materials, making them more susceptible to damage from impacts or stress. High humidity accelerates the deterioration of wood siding, promoting fungal growth and rot, while also impacting the performance of some less durable paints and finishes. For example, in arid climates, wood siding might dry out and crack, requiring more frequent maintenance than in humid climates where it may be prone to rot. Vinyl siding, due to its inherent flexibility, generally handles temperature fluctuations better than wood but can become brittle in extremely cold climates if not installed correctly. Fiber cement siding, being less susceptible to moisture and temperature changes, generally performs well across a wide range of climates. However, even fiber cement can experience some minor expansion and contraction with extreme temperature swings, though generally less significantly than wood or vinyl.

Installation and Longevity

Source: storables.com

Proper installation is paramount to achieving the maximum lifespan of your house siding. A seemingly small mistake during installation can significantly reduce the siding’s longevity, leading to premature damage and costly repairs. Understanding the crucial aspects of installation and employing best practices will ensure your siding investment protects your home for years to come.

The quality of materials is only half the battle; the other half rests squarely on the expertise of the installation process. Improper installation can lead to a cascade of problems, from water damage and pest infestations to structural issues and aesthetic flaws. These problems not only compromise the siding’s protective function but also dramatically shorten its lifespan, necessitating costly replacements far sooner than anticipated. For example, improperly installed vinyl siding might buckle or warp under temperature fluctuations, leading to early failure, while improperly fastened fiber cement siding could allow water penetration, causing rot and mold growth.

Potential Installation Issues and Their Impact

Improper installation can manifest in several ways, each with its own detrimental effects. For instance, gaps between siding panels can allow water to penetrate, leading to rot, mold, and structural damage. Incorrect flashing around windows and doors creates pathways for water intrusion, while insufficient nailing can cause the siding to loosen and eventually fall off. Furthermore, improper sealing of joints can lead to air leaks, increasing energy costs and potentially causing damage from moisture build-up. These issues, if not addressed promptly and correctly, can lead to extensive and costly repairs, even necessitating complete siding replacement.

Best Practices for House Preparation Before Siding Installation

Thorough preparation of the house before siding installation is crucial for ensuring a long-lasting and effective result. This involves several key steps that contribute to a successful and durable installation.

- Thorough Inspection and Repair of Existing Walls: Addressing any underlying issues such as rot, insect damage, or loose sheathing before installing new siding is vital. This preventative measure prevents future problems and ensures a solid foundation for the new siding.

- Proper Sheathing and Underlayment: Using high-quality sheathing and underlayment materials creates a moisture barrier and provides a stable surface for the siding. This helps prevent water damage and enhances the longevity of the siding.

- Accurate Measurements and Planning: Precise measurements and careful planning are crucial to ensure the siding is installed correctly and efficiently. Accurate planning minimizes waste and ensures a professional-looking finish.

- Installation of Flashing and Sealants: Correctly installing flashing around windows, doors, and other penetrations is essential to prevent water from entering the wall system. Using high-quality sealants ensures a watertight seal around all joints and seams.

- Appropriate Ventilation: Ensuring adequate ventilation behind the siding prevents moisture buildup, which can lead to rot and mold. Proper ventilation is especially crucial in climates with high humidity.

Cost and Value Considerations: Most Durable Siding For House

Choosing the right siding not only impacts your home’s aesthetics but also significantly influences its long-term cost. Understanding the initial investment, projected lifespan, and potential for cost savings is crucial for making an informed decision. This section will compare the costs of different durable siding options and explore how your choice affects both your immediate expenses and the overall value of your property.

Initial costs vary greatly depending on the material, labor costs in your region, and the complexity of your home’s exterior. Long-term cost savings, however, can offset higher initial investments. Durable siding often requires less maintenance and fewer repairs over its lifespan, leading to significant cost advantages in the long run. The choice also directly affects curb appeal and, consequently, your home’s market value.

Siding Cost Comparison

The following table provides a general comparison of initial costs, estimated lifespans, and annualized costs for three common durable siding options. These figures are estimates and can vary based on factors like material quality, labor rates, and project size. Always obtain multiple quotes from reputable contractors for your specific project.

| Siding Type | Initial Cost (per sq ft, estimate) | Estimated Lifespan (years) | Approximate Annual Cost (per sq ft) |

|---|---|---|---|

| Fiber Cement | $8-$15 | 50-80 | $0.10-$0.30 |

| Vinyl | $4-$10 | 20-40 | $0.25-$0.50 |

| Engineered Wood | $6-$12 | 30-50 | $0.12-$0.40 |

Long-Term Cost Savings

Choosing durable siding translates to substantial long-term cost savings. High-quality materials require less frequent painting, cleaning, and repair. For instance, fiber cement siding, with its superior resistance to weather damage and pests, may require minimal maintenance for decades, unlike vinyl siding which might need occasional cleaning or repair of damaged sections. These reduced maintenance costs add up significantly over the lifespan of the siding. Moreover, less frequent repairs mean fewer disruptions and lower associated labor costs. The reduced need for replacement also adds to the long-term savings.

Impact on Home Value and Curb Appeal

The type of siding you choose dramatically impacts your home’s curb appeal and, subsequently, its market value. A well-maintained home with attractive siding instantly enhances its visual appeal, making it more desirable to potential buyers. Durable, high-quality siding, such as fiber cement, can significantly increase your home’s resale value compared to less durable options that may show signs of wear and tear more quickly. A visually appealing exterior not only attracts buyers but also potentially commands a higher selling price. For example, a home with newly installed fiber cement siding might fetch a higher price than a comparable home with outdated, weathered vinyl siding.

Maintenance and Repair

Proper maintenance is crucial for extending the lifespan of your house siding and preserving its aesthetic appeal. Regular inspections and timely repairs can prevent minor issues from escalating into costly replacements. Understanding your siding type and its specific needs is key to effective maintenance.

Simple Maintenance Schedule for Different Siding Types

A regular maintenance schedule tailored to your siding type will significantly impact its longevity. Neglecting maintenance can lead to premature deterioration and expensive repairs. The frequency of these tasks will depend on your climate and the exposure your home receives.

- Vinyl Siding: Inspect annually for cracks, dents, or loose panels. Clean with a mild detergent and water solution twice a year, using a soft brush. Repair minor damage promptly using vinyl patching kits.

- Fiber Cement Siding: Inspect twice a year for cracks, damage, or loose caulking. Clean with a pressure washer (low pressure) once or twice a year. Repaint or restain every 5-7 years, depending on exposure to the elements.

- Wood Siding: Inspect quarterly for signs of rot, insect infestation, or damage. Clean with a mild detergent and water solution at least twice a year. Repaint or restain every 2-3 years to protect against moisture damage.

- Metal Siding: Inspect annually for dents, rust, or loose panels. Clean with a mild detergent and water solution or pressure washer (low pressure) as needed. Touch up paint as necessary to prevent rust.

Identifying and Addressing Common Siding Problems

Early detection of siding problems is vital for preventing significant damage and costly repairs. Recognizing the signs of common issues allows for prompt and effective action.

- Cracks: Cracks in siding can be caused by impact, settling, or age. Small cracks can often be repaired with caulk or patching compounds appropriate for the siding material. Larger cracks may require replacing the damaged section.

- Discoloration: Discoloration can indicate mildew, algae growth, or fading. Cleaning with a suitable solution (bleach solution for mildew, for example, but always test in an inconspicuous area first) can often restore the original color. For fading, repainting or restaining may be necessary.

- Impact Damage: Dents, holes, or other impact damage should be repaired immediately to prevent further deterioration and water intrusion. Repair methods vary depending on the siding material; some may require replacement of the damaged section.

Cleaning and Protecting Siding Materials

Regular cleaning and protective measures are essential for maintaining the appearance and longevity of your siding. The cleaning method should always be appropriate for the siding material to avoid damage.

- Vinyl Siding: Clean with a mild detergent and water solution, using a soft brush or sponge. Avoid abrasive cleaners or high-pressure washers, which can damage the surface.

- Fiber Cement Siding: Use a low-pressure washer to remove dirt and debris. Avoid using harsh chemicals that could damage the surface. Repainting or restaining helps protect against moisture damage.

- Wood Siding: Clean with a mild detergent and water solution. Regularly inspect for signs of rot or insect infestation. Repainting or restaining with a high-quality exterior paint or stain is crucial for protection.

- Metal Siding: Clean with a mild detergent and water solution or a low-pressure washer. Touch up paint regularly to prevent rust and maintain its protective layer.

Environmental Impact

Source: lensingbuildingspecialties.com

Choosing siding involves more than just aesthetics and durability; it significantly impacts the environment. The manufacturing process, material sourcing, and eventual disposal all contribute to a material’s overall environmental footprint. Understanding these impacts allows for informed decisions that minimize your home’s environmental burden.

Different siding materials have vastly different environmental profiles. Factors such as energy consumption during manufacturing, transportation distances, and the recyclability or disposal methods all play a role. Some materials boast lower carbon footprints due to the use of recycled content or sustainable manufacturing practices, while others present challenges in terms of waste generation and resource depletion.

Manufacturing Processes and Emissions

The way siding is made has a big impact on the environment. For instance, making vinyl siding often involves using fossil fuels and releasing harmful chemicals into the air. On the other hand, while making fiber cement siding uses more energy, it’s made from readily available materials like cement and wood fibers. Wood siding can have a lower carbon footprint if it’s harvested sustainably, but pressure-treated lumber often uses chemicals that can harm the environment. Metal siding, which is often made from recycled aluminum or steel, generally has a lower carbon footprint than vinyl, but mining and processing the raw materials still take a toll on the environment.

Recycled Content and Sustainable Sourcing

Manufacturers are embracing sustainability by incorporating recycled materials into siding production. Vinyl siding options made from post-consumer recycled PVC reduce reliance on virgin materials. Aluminum and steel siding are often made from significant percentages of recycled metal, minimizing the need for new metal extraction. Wood siding sourced from sustainably managed forests contributes to responsible forestry practices. Look for siding with certifications like FSC (Forest Stewardship Council) to ensure the wood comes from responsibly managed forests. The use of recycled content reduces landfill waste and lowers the overall environmental impact.

Energy Efficiency and Long-Term Impact

Durable siding helps homes be more energy-efficient, which reduces their impact on the environment over time. High-performance siding materials with good insulation properties can minimize heat loss in winter and heat gain in summer, reducing the need for heating and cooling. This leads to lower energy consumption and fewer greenhouse gas emissions from power plants. For example, fiber cement siding’s density provides better insulation than vinyl siding. Properly installed and insulated metal siding can also provide excellent thermal performance. The long-term energy savings from high-performance siding offset some of the initial environmental costs associated with its production and installation.

Final Conclusion

Source: contemporist.com

Choosing the most durable siding for your house is a wise investment that pays off in the long run. By understanding the pros and cons of different materials, employing proper installation techniques, and implementing a regular maintenance schedule, you can significantly extend the lifespan of your siding and enhance your home’s value. Remember to consider your budget, climate, and aesthetic preferences when making your final decision. With the right information and planning, you can confidently select a siding solution that protects your home and enhances its beauty for decades to come.

Essential Questionnaire

What is the average lifespan of different siding materials?

Lifespans vary greatly depending on material, climate, and maintenance. Vinyl siding can last 20-40 years, fiber cement 50-75 years, and wood siding, with proper maintenance, can last 50+ years.

Can I install siding myself?

While DIY is possible for some siding types, professional installation is generally recommended for optimal results and warranty coverage. Improper installation can significantly reduce siding lifespan.

How often should I clean my siding?

A yearly cleaning with a pressure washer (low pressure setting) is recommended for most siding types. More frequent cleaning may be necessary in areas with heavy pollution or tree cover.

What are the signs of siding damage that require immediate attention?

Look for cracks, significant discoloration, warping, water damage, or loose or missing pieces. Address these issues promptly to prevent further damage.

How does siding impact my home’s energy efficiency?

Certain siding materials, like fiber cement, offer better insulation and can contribute to lower energy bills compared to others, such as vinyl. Proper installation also plays a crucial role in energy efficiency.